Case ID: MJ-CS-24-005

A client from the United States specializing in high-performance turbocharging components for racing vehicles contacted us with a technical drawing to develop custom turbo gaskets. They required a multi-layer stainless steel gasket that could meet the demanding performance standards of their advanced turbo systems.

What the Drawing Included and What MJ GASKET Needed

The technical drawing provided precise dimensions, giving us a clear understanding of the gasket’s shape and fitment. However, it did not specify the exact stainless steel grade required for production. Since material selection plays a critical role in gasket performance, we consulted further with the client to clarify their needs.

300 Series Stainless Steel for High-Performance Turbo Applications

For high-performance turbo applications, 300 Series Stainless Steel is often the preferred choice due to its exceptional heat resistance, corrosion resistance, and durability under extreme conditions. To ensure the gasket meets the client’s performance expectations, MJ GASKET required confirmation on the specific grade within the 300 Series, such as 301 or 304 stainless steel, each offering distinct advantages in strength, flexibility, and environmental resistance.

Comparing 301 vs. 304 Stainless Steel for Turbo Gaskets

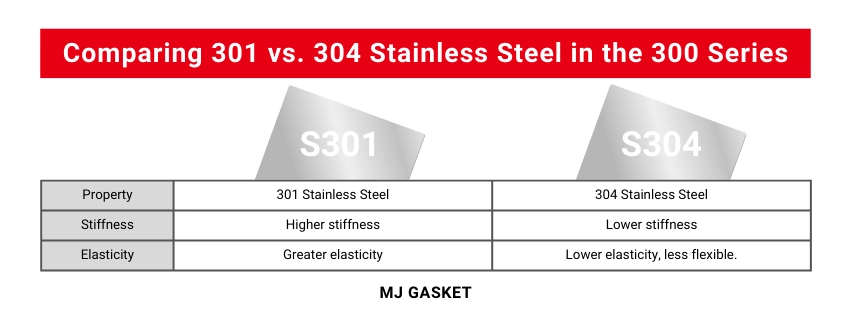

Stainless 301 and Stainless 304 are the most commonly used grades from the 300 Series stainless steel family for high-performance engine gaskets.

When selecting materials for turbo gaskets, the differences between 301 and 304 stainless steel play a crucial role in performance. These two grades vary in stiffness and elasticity, which affects their suitability for specific applications.

1. Stiffness

301 Stainless Steel has higher stiffness due to its strong work-hardening ability. After cold working (such as rolling or forming), its strength and hardness increase significantly, making it stiffer than 304 Stainless Steel.

304 Stainless Steel, on the other hand, has lower stiffness since it doesn’t harden as much during cold working, resulting in generally lower strength compared to 301 under similar conditions.

2. Elasticity

301 Stainless Steel offers greater elasticity, especially after cold working, providing excellent spring-back characteristics. This makes it ideal for applications requiring high resilience, such as springs and clamps.

304 Stainless Steel has lower elasticity because its cold-working hardening effect is weaker, limiting its elastic range in comparison to 301 Stainless Steel.

Material Recommendation and Sample Testing

For turbo gasket applications where stiffness and elasticity are critical, 301 stainless steel is the better choice. However, if corrosion resistance and weldability are the main concerns, 304 stainless steel is preferred.

In this case, we provided the client with professional guidance on selecting the appropriate grade from the 300 Series stainless steel and offered samples of both 301 and 304 for testing on their turbochargers. This ensured the final gasket would meet their performance goals.

Need Custom Turbo Gaskets? Let’s Talk.

If you’re also developing aftermarket upgraded turbos and need custom gaskets tailored to demanding applications, MJ GASKET is ready to deliver high-performance solutions built around your needs. Just send us your detailed technical drawing at gasket@mj-deyi.com.tw

Let’s build it together!