Case ID: MJ-CS-14-007

A locomotive engine specialist based in the United States contacted MJ Gasket with a requirement for a gasket used on Caterpillar 3500 Series locomotive engines. The requested part is a rubber-bonded-to-metal gasket, also known as an edge bonded seal. Given the demanding conditions in locomotive applications, such as continuous operation, high engine temperatures, and vibration. The client requested that the rubber material used in the gasket should meet a compression set requirement of under 20%.

What causes compression set?

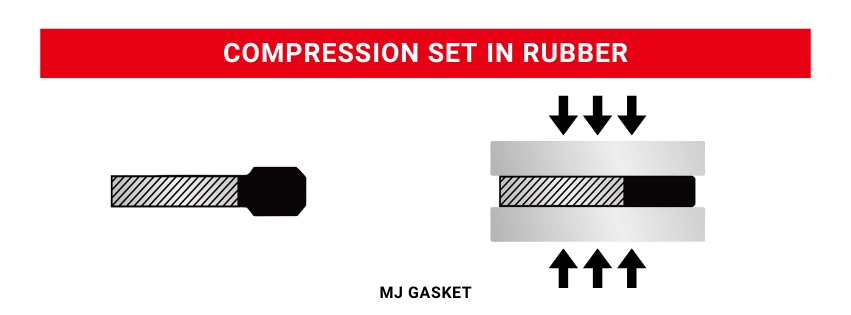

When a rubber-bonded-to-metal gasket stays under compression for an extended period, the rubber may gradually conform to the shape of the contact surface. After the load is removed, it might not return to its original thickness or profile. This phenomenon is known as compression set and typically appears as a permanent deformation in areas that were compressed.

For more on how compression set affects rubber sealing performance, see our article: What is Compression Set in Rubber Gasket?

How to Minimize the Risk of Compression Set?

To maintain sealing performance over time, it’s important to minimize the likelihood of compression set. One of the most effective ways to do this is by carefully evaluating the gasket material based on the intended application. Not all rubber compounds respond the same under prolonged compression. Some are more resilient and better suited for high-temperature or high-pressure environments.

Beyond material selection, external factors such as exposure to heat, chemicals, and mechanical stress must also be taken into account. A mismatch between the gasket’s properties and the system conditions can accelerate permanent deformation.

Effective sealing isn’t just about selecting a rubber—it’s about finding the right combination of material hardness, elasticity, thermal stability, and chemical resistance. By aligning material capabilities with system requirements, the chances of compression set can be significantly reduced.

Conclusion & Takeaways

This project demonstrates the importance of both material selection and dimensional evaluation in addressing compression set challenges. By identifying the right rubber compound and assessing potential fit issues, we helped the client minimize the risk of permanent deformation and maintain sealing reliability over time.

Understanding how compression set impacts rubber gaskets is key to choosing the right solution from the start.

Learn more in our guide: What is Compression Set in Rubber Gasket?