The Role of Cylinder Head Gaskets in Heavy-Duty Engines

The cylinder head gasket plays a critical role in sealing the engine block and cylinder head, maintaining compression within the combustion chamber while preventing coolant and oil from leaking into nearby areas. Especially for heavy-duty and high-performance diesel engines, the cylinder head gasket must withstand extreme combustion pressure and temperature fluctuations while maintaining a secure and long-lasting seal.

What are head gaskets made of?

To meet the harsh demands of heavy-duty engines, cylinder head gaskets are made from durable materials to handle extreme heat and pressure. Common materials include composite graphite, multi-layer steel, metal bonded with rubber, and sandwich-type.

Top 3 Cylinder Head Gasket Material for Heavy-duty Engines

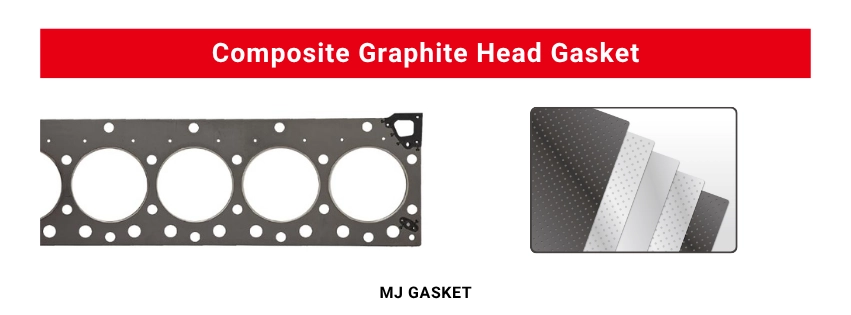

1. Composite Graphite

Graphite is one of the most commonly used materials for cylinder head gaskets in heavy-duty engines. Thanks to its excellent thermal resistance and flexibility, it can handle high temperatures and pressures without losing its sealing ability. Composite graphite gaskets also adapt well to surface irregularities, making them ideal for engines that undergo repeated thermal cycling. This material provides a strong, reliable seal while reducing the risk of leaks over time.

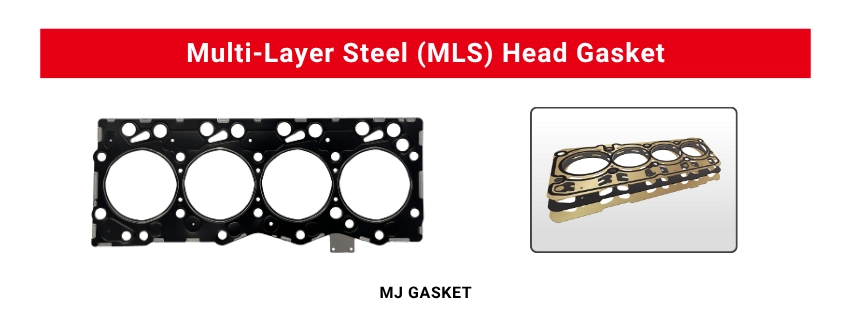

2. Multi-Layer Steel (MLS)

Multi-Layer Steel (MLS) gaskets are built from multiple layers of stainless steel, offering superior strength, durability, and resistance to high combustion pressure. While they may not conform to surface imperfections as easily as graphite, they perform exceptionally well when installed with precision-machined surfaces and correct clamping force.

Read more: How We Make MLS Custom Head Gasket?

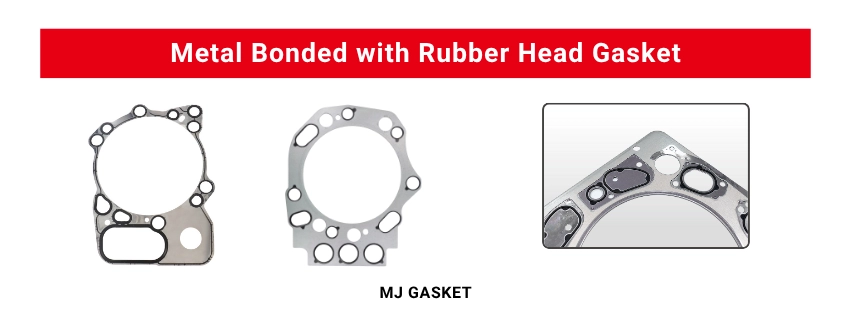

3. Metal Bonded with Rubber

Metal bonded with rubber head gaskets have a strong metal base combined with rubber to provide a reliable and flexible seal. While the metal part is rigid and provides strength and support, the rubber offers elasticity that helps seal against minor surface imperfections and adjusts for the expansion caused by engine heat between the cylinder head and engine block. This combination prevents leaks of combustion gases and coolant while staying durable under the high temperatures and pressures common in heavy-duty engines.

Head Gasket Material for Popular Heavy-Duty Engine Models

In heavy-duty engines, the cylinder head gasket must withstand extreme pressure, high temperatures, and long-term stress. That’s why using a high-quality head gasket material is essential to maintain engine performance and prevent failure.

At MJ, we supply aftermarket gaskets made from durable materials like Graphite, Multi-Layer Steel (MLS), and Metal Bonded with Rubber—all widely recognized in the industry for their strength, sealing ability, and long-term reliability.

Here are some of the engine models we support, along with the head gasket material used:

- Caterpillar: C7, C9, C10, C12, C13, C15 – Head gasket material: Graphite, MLS

- Cummins: QSK19, KT50, QSK45, QSK45G, QSK60, QSK78, ISB, ISX12, ISX15 – Head gasket material: Metal Bonded with Rubber, Graphite, MLS

- Detroit Diesel: S60, DD13, DD15 – Head gasket material: Graphite, MLS with Metal Bonded with Rubber

- MTU: Series 60, Series 396, Series 2000, Series 4000 – Head gasket material: Graphite, Metal Bonded with Rubber

- Volvo: D12, D13 – Head gasket material: Metal Bonded with Rubber

- Navistar: DT466E, Maxxforce 7, Maxxforce 13 – Head gasket material: Graphite, Metal Bonded with Rubber

- Paccar: MX-11, MX-13 – Head gasket material: MLS, Metal Bonded with Rubber

If you found this information helpful and would like to learn more about gasket materials or discuss which types are used in your engine applications, feel free to contact us using the button at the bottom right. We’re always happy to share our knowledge and experience in aftermarket gasket solutions.

Quick FAQ about Cylinder Head Gasket Material

What is head gasket material made of?

Head gaskets are made of durable materials like composite graphite, multi-layer steel (MLS), and metal bonded with rubber to handle extreme heat and pressure.

What is the best material for a head gasket?

There isn’t a single “best” head gasket material — it depends on each engine’s needs. For heavy-duty engines, composite graphite and multi-layer steel (MLS) are the most common choices.

Is a graphite head gasket better than steel?

Graphite seals better on uneven surfaces, while steel offers higher strength and longer lifespan.