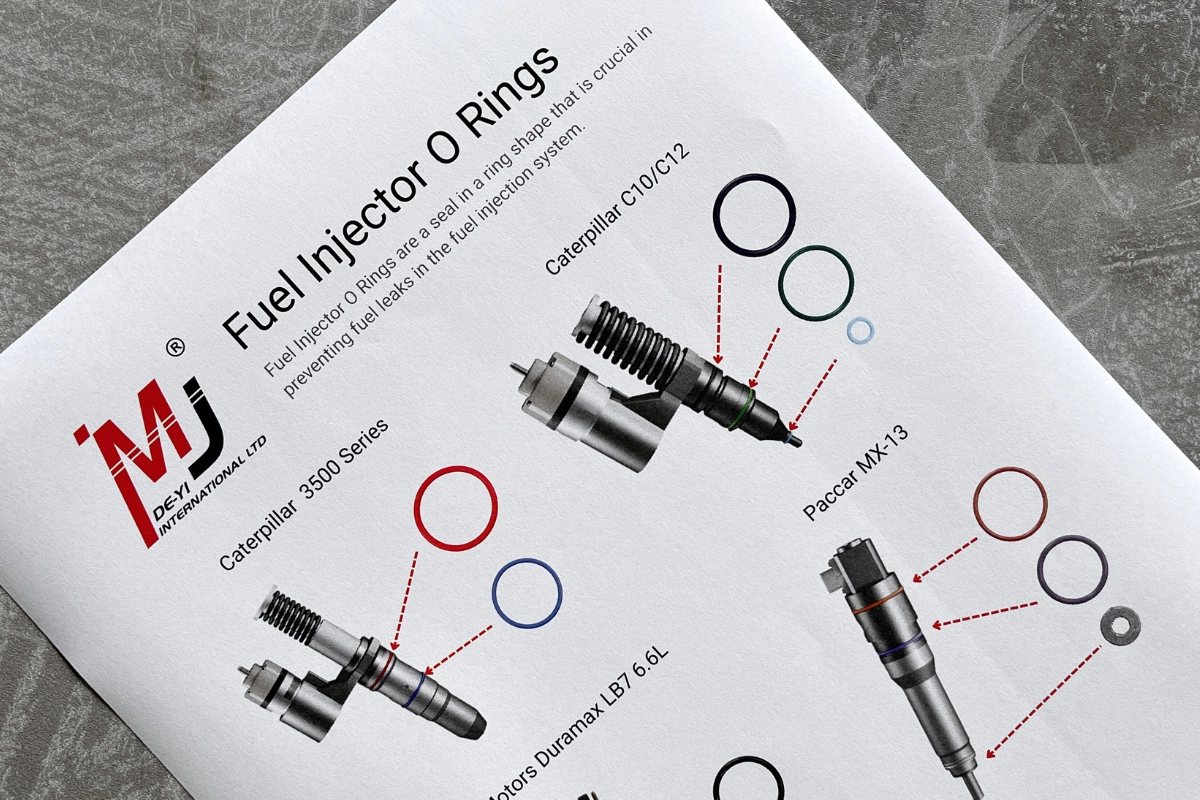

Fuel Injector O Rings are small seals in a ring shape that are crucial for preventing fuel leaks in the fuel injection system. Fuel injectors play a critical role in delivering the right amount of fuel to the engine’s combustion chamber, ensuring that the fuel is delivered precisely. Fuel Injector O Rings seal the connection between the fuel injectors and the cylinder head to prevent leakage.

Made of rubber or other synthetic materials, Fuel Injector O Rings are designed to resist the harsh chemicals and high temperatures present in fuel systems. These rubber materials are resistant to heat, oil, and fuel, but over time, they may wear out or become damaged, leading to fuel leaks.

Replacing Fuel Injector O Rings is an essential maintenance task that helps prevent costly repairs and ensures the proper functioning of the fuel system. It is recommended to inspect and replace the O-rings as needed during regular vehicle maintenance to avoid potential safety hazards.

Table of Contents

What types of materials are used in fuel injector O rings?

There are several rubber materials, including FKM, NBR, HNBR, EPDM, Silicone, etc. For fuel injector o rings, the common rubber is FKM, NBR and HNBR.

- FKM: Known for its excellent resistance to high temperatures (up to over 200°C), acids, alkalis, fuels, and most chemicals. Although it is more expensive, FKM performs stably under harsh environments. It is the most commonly used rubber material for Fuel Injector O Rings.

- NBR: The most common material for O-rings, offering a reasonable cost with good resistance to oil and abrasion.

- HNBR: Provides excellent resistance to fuel oils and lubricants. Its highly saturated molecular structure gives it strong heat resistance (approximately 130–180°C), outstanding chemical and ozone resistance, and superior resistance to compression set. HNBR also features high tensile strength, exceptional tear resistance, and excellent wear performance.

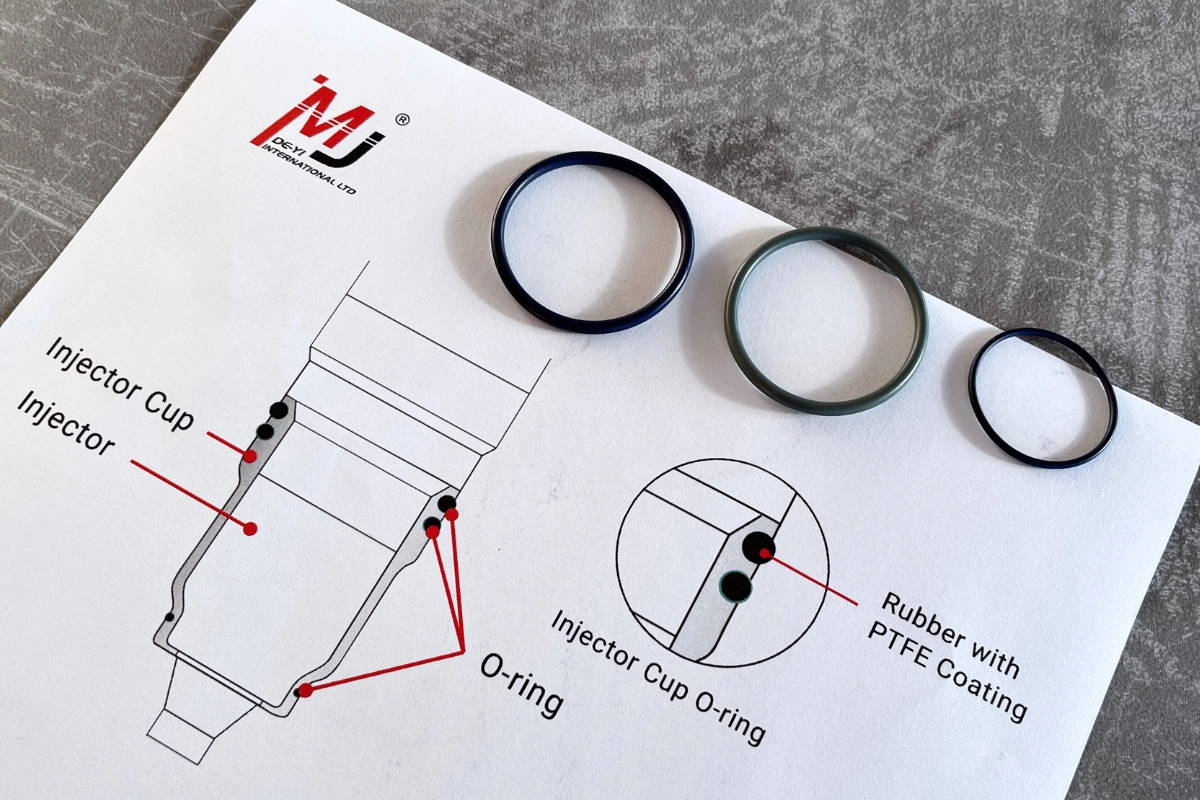

To enhance resistance to chemicals, high temperatures, and friction, many Fuel Injector O Rings are not only made from heat-resistant, high-pressure, and corrosion-resistant rubber but are also coated with PTFE. This combination improves the O-ring’s ability to withstand wear, reduce friction, and maintain long-lasting sealing performance.

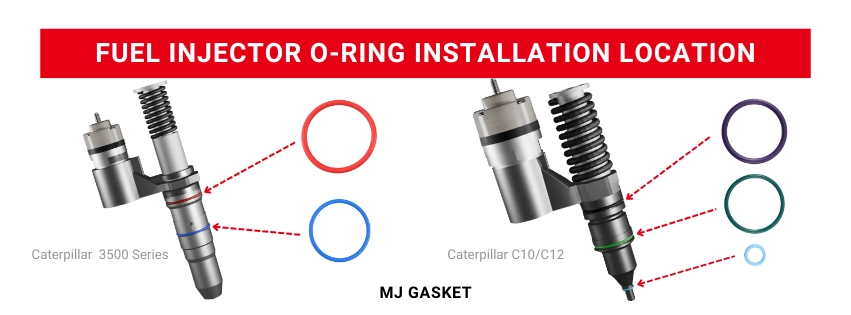

Fuel Injector O-Ring Installation Location

The Fuel Injector O Rings are typically installed on the fuel injector body, serving as seals between the injector and the cylinder head. Each fuel injector usually has more than one O-ring, and the number and position depend on the injector’s design.

To access the Fuel Injector O Rings, the fuel rail often needs to be removed, and the fuel injectors disconnected from the fuel lines. It is crucial to follow the OEM installation procedures and use the correct tools to ensure proper sealing and prevent fuel system damage.

Because fuel injector O-ring installation involves handling pressurized components and precise sealing, it is recommended to have a professional mechanic or technician perform the installation to ensure safety and reliability.

Bad Fuel Injector O Ring Leak Symptoms

When inspecting for fuel leaks around the injectors, it is important to first determine whether the leak originates from the Fuel Injector O Rings or from the injector’s internal components.

- O-Ring Leak (External Leak): This occurs when the Fuel Injector O Rings become aged, deformed, or improperly installed, causing diesel fuel to seep from the joint between the injector and the cylinder head. When the engine is running and fuel system pressure builds up, the leak often becomes more visible around the outer area of the injector.

- Internal Injector Leak: This type of leak happens inside the injector due to internal seal failure, allowing fuel to drip into combustion chamber even when the injector is not operating (such as during engine shutdown or idling). Detecting this issue typically requires professional testing equipment and removing the injector for inspection.

To accurately identify the source of the leak, running the engine and observing fuel flow is the most direct method. However, because fuel is highly flammable, a serious leak in contact with hot components or sparks could lead to a fire. Therefore, it is strongly recommended to have a qualified technician perform the inspection, as they have the proper tools and safety knowledge to handle high-pressure fuel systems and minimize potential fire risks.

Common Causes of Fuel Injector O-Ring Failure

- Aging and Wear: Over time, Fuel Injector O Rings can become brittle, cracked, or deformed, resulting in loss of sealing ability.

- Exposure to Heat and Chemicals: Continuous exposure to high temperatures and fuel system chemicals can cause the O-rings to deteriorate or break down.

- Contamination: Dirt or debris trapped between the injector and the O-ring can damage the sealing surface, leading to leakage or premature failure.

- Improper Installation: Failure to follow correct torque specifications or over-tightening the injector during installation can cause early O-ring damage.

- Incorrect Material Selection: Using an O-ring material incompatible with the specific fuel system can lead to seal failure. It’s essential to use the correct material and size of Fuel Injector O Rings as recommended by the OEM.

When is it necessary to replace the O ring for fuel injectors?

Fuel Injector O Rings should be replaced when they show signs of wear, damage, or fuel leakage. Common symptoms of faulty O-rings include fuel odor, visible leaks, reduced engine performance, rough idling, or difficulty starting the engine.

In addition, it is recommended to replace the Fuel Injector O Rings whenever fuel injectors are removed, or during routine engine maintenance. Regular replacement helps prevent fuel leaks, maintain proper fuel injection performance, and avoid costly engine repairs in the long run.

Fuel Injector O-Ring Sealing Solution

We offer reliable Fuel Injector O-Ring sealing solutions for heavy-duty and pickup truck engines, ensuring leak-free performance, durability under extreme conditions, and stable fuel system operation.

Caterpillar Fuel Injector O Rings Kit

Reliable Aftermarket Fuel Injector O Rings for Caterpillar C10/C12, 3406E/C11/C13/C15/C16, and 3500 Series engines, ensuring proper sealing, leak prevention, and fuel system durability.

Cummins ISX15 Fuel Injector O Rings Kit 4025062

Fuel Injector O Rings for Cummins ISX/QSK15 4025062 provide secure sealing under high pressure to prevent leaks and maintain stable engine injection performance.

Detroit Diesel S60 Fuel Injector O Rings Kit 23537123

For Detroit Diesel S60 23537123 injectors, these Fuel Injector O Rings ensure strong sealing, reducing leakage risk and supporting efficient engine operation.

Volvo D11/D12/D13/D16 Fuel Injector O Rings Kit

Fuel Injector O Rings 276948 suitable for Volvo D11/D12/D13/D16 engines, offering durable sealing to protect against fuel leakage and maintain engine efficiency.

Paccar MX-13 Fuel Injector O Rings Kit

Fuel Injector O Ring Kit for Paccar MX-13 engines maintains reliable sealing against fuel leaks, supporting consistent performance in commercial diesel applications.

How Are Injector Seals Installed On Injectors?

Quick FAQ about Fuel Injector O Rings

What are fuel injector O rings?

Fuel Injector O Rings are small rubber sealing rings installed on the fuel injector body to prevent fuel leaks, maintain pressure, and ensure proper fuel delivery into the combustion chamber.

How many o rings on fuel injectors?

Most fuel injectors use more than one Fuel Injector O Ring. The quantity and placement vary depending on the injector design and engine model.

Do you need special O-rings for fuel injectors?

Yes. Fuel Injector O Rings must be made from fuel-resistant and heat-resistant materials such as FKM coated with PTFE, and must match the specific size and specifications required by the fuel system.

What are the symptoms of a bad fuel injector O-ring?

Common symptoms include fuel odor, visible leaks, poor engine performance, rough idling, hard starting, and increased fuel consumption. Severe leaks can also pose a fire risk.

Can you reuse fuel injector O rings?

No. Fuel Injector O Rings should not be reused. Once compressed and exposed to heat and chemicals, they can lose sealing capability. Always replace O-rings during injector service or removal.

Read more about fuel injector seals: Injector Cup Seal Failure Cause and Sealing Solutions