Table of Contents

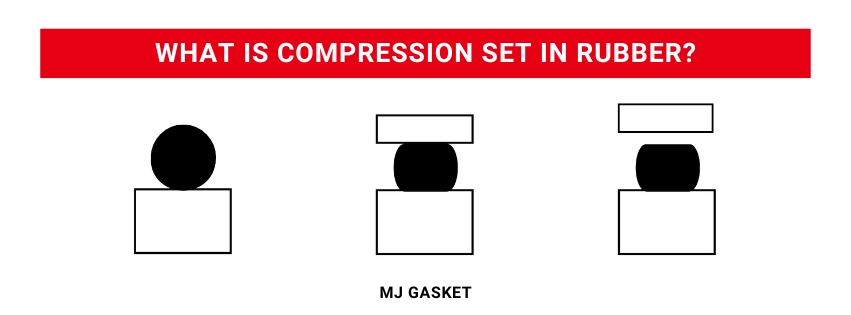

What is compression set in rubber?

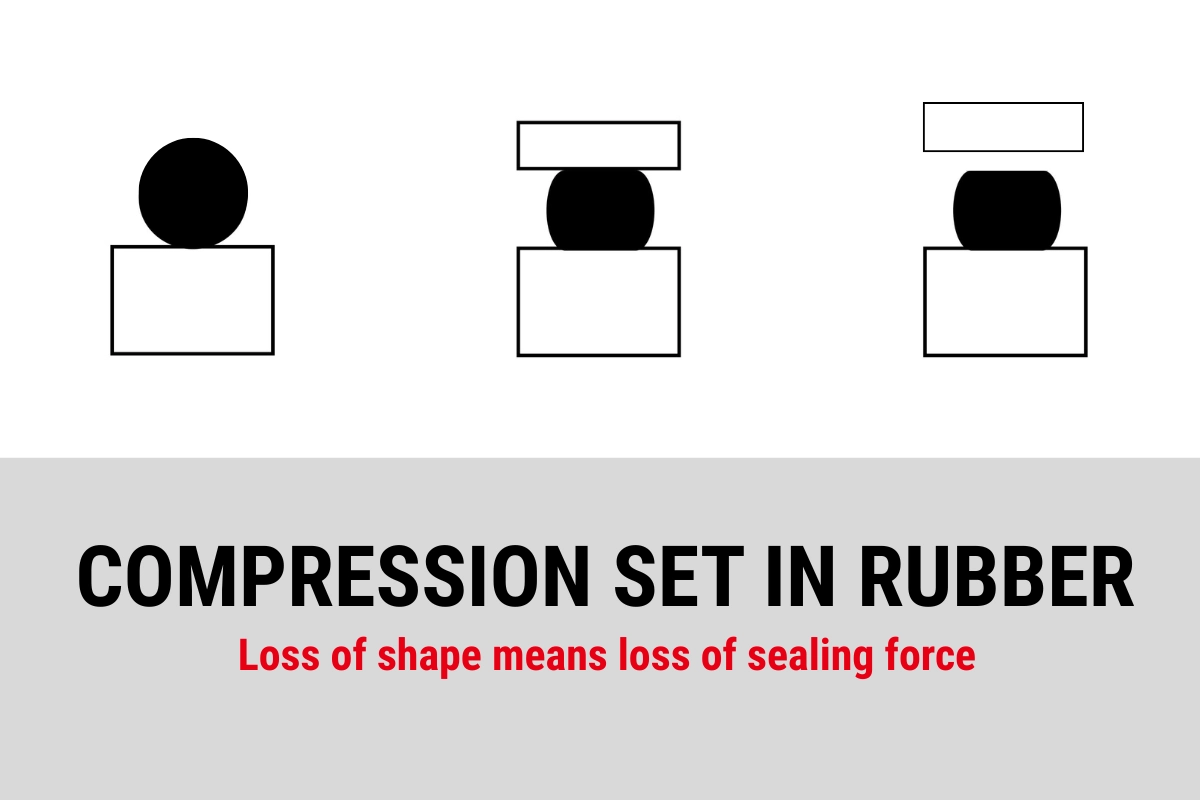

Compression set is a measure used for elastomeric materials, such as rubber, to describe how much a material fails to return to its original shape after being compressed. It is expressed as a percentage of the original dimensions. When a rubber gasket experiences compression set, it cannot fully return to its original round cross-section even after the compressive force has been removed.

How is compression set caused?

When a rubber gasket sits in a groove under pressure for a long time, it gradually conforms to that shape. Even after you release the pressure, the gasket won’t fully return to its original form. On a cross-section, you might notice the top and bottom surfaces look flattened rather than round.

How is compression set measured?

Compression set is evaluated through a laboratory test that determines how much an elastomer recovers after being compressed. The procedure follows standard methods defined in ASTM D395. In this test, a rubber sample is placed in a jig and compressed under a specific force and temperature for a fixed period.

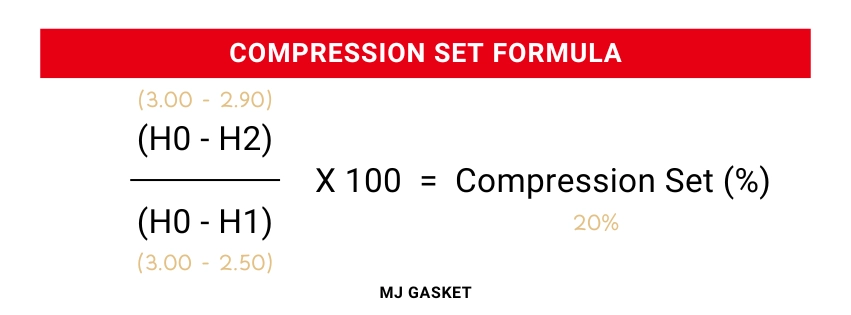

After the compression phase, the sample is removed from the jig and left at room temperature for 30 minutes. The height of the sample is then measured to assess how much it has returned to its original shape. The compression set is calculated using the following formula:

Compression Set (%) = [(H0 – H2) / (H0 – H1)] * 100

Here, H0 is the original height of the sample, H1 is the height while under compression, and H2 is the height after recovery. For example, if a gasket has an original height of 3.00 mm (H0), is compressed to 2.50 mm (H1), and recovers to 2.90 mm (H2), the resulting compression set is 20%.

A value of 0% means the sample has fully recovered, while 100% indicates no recovery. A lower compression set value shows that the rubber can regain its shape more effectively.

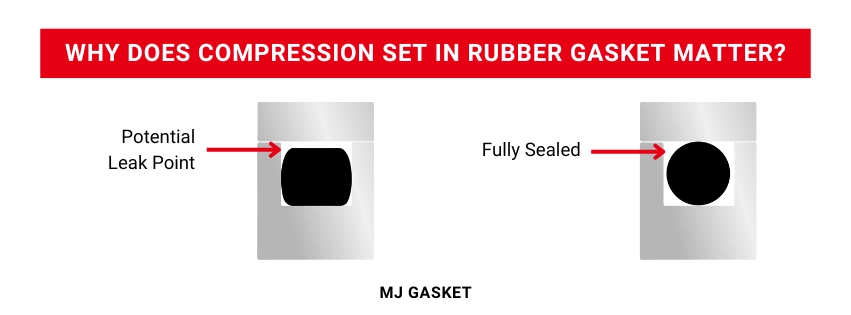

Why does compression set in rubber gasket matter?

Compression set gives insight into how long a gasket can maintain its shape and function. If a rubber gasket takes a permanent set, it may become flattened and lose the ability to maintain contact pressure, which can reduce its sealing capability and increase the risk of leakage over time. In contrast, a rubber gasket with low compression set tends to keep its form and provides more stable sealing over extended use.

How can compression set be avoided?

Seal failure caused by compression set can lead to significant financial loss and damage to a company’s reputation. To prevent this issue, selecting the right rubber sealing material is essential. The material choice should consider several factors, such as the specific application and how long the seal will remain under compression.

Environmental conditions also play a key role. These include the temperatures the rubber gasket will be exposed to, the presence of chemical substances in the surrounding environment, and the pressure levels involved in the system. Choosing a material that can withstand these conditions helps reduce the risk of permanent deformation and maintains sealing effectiveness over time.