Table of Contents

What is injector cup?

An injector cup, also called an injector sleeve, is a metal part placed between the cylinder head and the fuel injectors. Why does the fuel injector system need injector cups? During engine combustion, the injectors are exposed to high temperature and high pressure, which can cause them to overheat and injector failure.

The injector cup fits between the injector and the cylinder head, acting as a sleeve that separates the injector from direct contact with the combustion chamber. Engine coolant flows around the outside of the injector cup, and this indirect cooling effect helps draw heat away from the injector. By preventing excessive heat buildup, the injector cup plays a critical role in protecting the injector from damage, ensuring stable fuel delivery and extending injector life.

What if the injector cup and seal fail?

The injector cup and the injector cup seal are critical components of the fuel injector system. If an injector cup fails or the cup seal loses its integrity, diesel can leak into the cooling system. This not only causes fuel loss and reduces engine performance, but also disrupts the cooling system, lowering heat-exchange efficiency and potentially damaging cooling components.

In short, when the injector cup seal fails, it leads to cross-contamination between fuel and coolant, which can severely impact engine operation. Once the coolant is contaminated with fuel, it must be completely flushed and replaced.

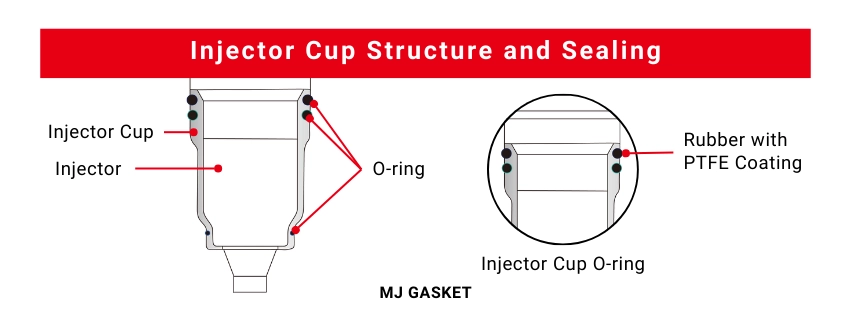

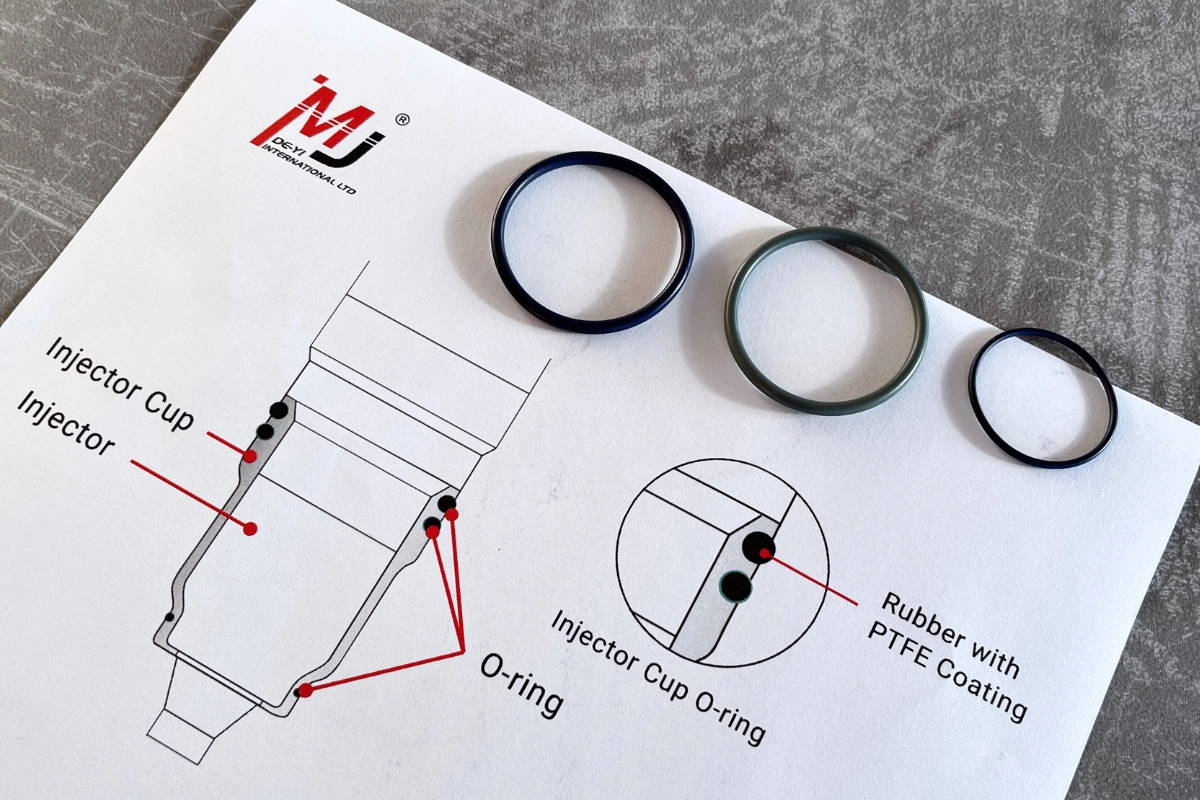

Injector Cup Seal Materials

As mentioned above, injector cup seals sit between the cylinder head and the injectors, which places them in an area exposed to extreme temperature and pressure. Because of this, the choice of material for the injector cup seal is critical.

The most common material for injector cup seal FKM (Fluorocarbon) rubber with a PTFE (Polytetrafluoroethylene) coating. FKM provides excellent resistance to chemicals, oil, and high heat. When coated with PTFE, it gains additional strength, PTFE is a high-performance plastic known for outstanding resistance to chemicals, high temperatures, and friction.

In certain applications, such as the Caterpillar 3406E/C15 injector cup seal, the material is upgraded to serve different sealing functions. Caterpillar part numbers 1662903 and 1662904 are O-rings for the injector cup. Both share the same dimensions (ID 1.362 in × CS 0.103 in, AS568 dash size 126), but are placed in different positions and use different rubber materials: 1662903 is installed at the top position, while 1662904 is installed at the middle position and OEM specifies different rubber materials:

- 1662903 (top position) – made from FKM with PTFE coating, designed to seal against fuel.

- 1662904 (middle position) – made from TFE/P (Tetrafluoroethylene Propylene) with PTFE coating, designed to seal against coolant or water.

Like FKM, TFE/P also offers excellent resistance to chemicals, heat, and oil, but its biggest advantage is superior resistance to water and steam. In short, the top seal (1662903) protects against fuel leakage, while the middle seal (1662904) is optimized for coolant and water sealing.

Injector Cup Seal for Heavy-duty Diesel Engines

We supply high-quality injector cup seals made for durability and performance in heavy-duty diesel engines. Capable of withstanding extreme heat, pressure, and chemical exposure, these seals help prevent fuel and coolant cross-contamination while maintaining reliable engine performance.

Caterpillar Injector Cup Seal

Reliable injector cup seals for Caterpillar 3406E/C15 (1662903/1662904/9X7430) and 3126B/C7/C9 (3107255/3107257). These seals hold up under demanding operating conditions and provide secure sealing for both fuel and coolant passages.

Detroit Diesel Injector Cup Seal

Durable injector cup seals for Detroit Diesel DD15 (A0249976445), DD15 Gen5 (A0319977345), and Series 60 (23534743). Built with premium rubber materials and coatings, they help reduce downtime and support longer injector service life.

Volvo Injector Cup Seal

Trusted injector cup seal for Volvo D13 (2053648). Manufactured with materials that resist heat, pressure, and chemical attack, ensuring stable sealing performance in heavy-duty applications.

Quick Q&A for Injector Cup

What is an injector cup?

An injector cup, also called an injector sleeve, is a metal component installed between the cylinder head and fuel injector. It separates the injector from direct combustion chamber exposure and allows coolant to flow around it, helping to control heat and extend injector life.

What happens if the injector cup or seal fails?

If the injector cup or its seal loses integrity, fuel can leak into the cooling system. This leads to fuel loss, reduced engine performance, coolant contamination, and decreased heat-exchange efficiency—potentially causing overheating and engine damage.

What materials are used for injector cup seals?

Injector cup seals are commonly made from FKM (fluorocarbon) rubber with PTFE coating, offering strong resistance to heat, fuel, and chemicals. In some applications, TFE/P rubber with PTFE coating is used for improved resistance to water and steam.