Table of Contents

What is an oil pan gasket?

The oil pan gasket, also called oil sump gasket, sits between the oil pan and the engine block, creating a tight seal that keeps engine oil contained inside the pan. It prevents oil from leaking out as it circulates through the engine for lubrication and cooling.

Because the oil pan is exposed to constant temperature changes and vibration, the oil pan gasket material can wear out over time. When that happens, oil can start to escape from the seal between the oil pan and the engine block.

In the next section, we’ll go over the common signs of oil pan gasket failure and what to look for when leaks occur.

Oil Pan Gasket Leak Symptoms

When the oil pan gasket starts to fail, you’ll usually notice some clear warning signs. Here are the most common symptoms:

Symptom #1: Oil spots under the vehicle – One of the first clues is fresh oil dripping or pooling beneath the engine after parking.

Symptom #2: Visible oil around the pan – Check the edges of the oil pan; a worn gasket often leaves wet or oily residue along the seal.

Symptom #3: Burning oil smell – Leaking oil may drip onto hot components like the exhaust, creating a noticeable burnt oil odor.

Symptom #4: Low engine oil level – If you frequently need to top up oil, it could be escaping from the oil pan area.

Spotting these signs early can help prevent further damage and keep your engine properly lubricated. Even a small oil leak, if ignored, can lead to a gradual drop in oil pressure and insufficient lubrication to critical engine components. Over time, this may cause premature wear on bearings, crankshafts, and other moving parts.

By addressing a leaking oil pan gasket as soon as possible, you not only avoid costly repairs but also maintain the overall efficiency and reliability of your engine. Regular inspection of the oil pan area and gasket condition during routine maintenance is a simple yet effective way to extend engine life and prevent downtime.

In the next section, we’ll take a closer look at the common materials used for oil pan gaskets and how each one contributes to sealing durability and long-term reliability.

Oil Pan Gasket Replacement

Before performing an oil pan gasket replacement, several common questions often come to mind: Can I reuse the old gasket? Should I choose an OEM or aftermarket one? Which aftermarket brand can I trust? How do I know if the quality meets the required standard?

It’s generally not recommended to reuse any gasket, including the oil pan gasket. A used gasket may have inaccurate dimensions or weakened material strength after being exposed to heat, pressure, and oil. For example, a rubber oil pan gasket can lose its original shape due to rubber compression set, reducing its ability to seal properly. (Read more in this article to understand why rubber compression set matters.)

As for whether to choose OEM or aftermarket oil pan gaskets, both options have their pros and cons. OEM gaskets usually guarantee a perfect fit but come at a higher price. Aftermarket gaskets, on the other hand, often offer a more cost-effective solution—especially when sourced from reputable manufacturers that maintain strict material standards and dimensional accuracy. Choosing a trusted aftermarket brand ensures reliable sealing performance and long-term durability without overspending.

Once you have a new oil pan gasket, always follow the manufacturer’s service manual for a safe and effective oil pan gasket replacement. Proper cleaning of the sealing surfaces, applying the correct torque sequence, and avoiding overtightening are key steps to ensure a lasting seal. Taking the time to replace the gasket correctly not only prevents future leaks but also helps maintain the engine’s overall reliability.

The performance of the replacement largely depends on the oil pan gasket material itself. In the next section, we’ll look at the most common materials used for oil pan gaskets.

Oil Pan Gasket Material

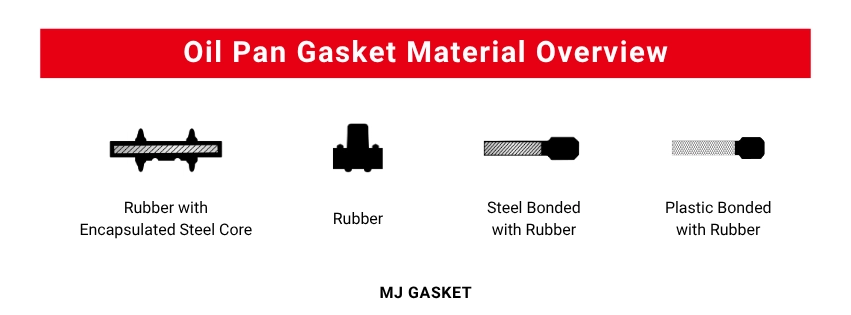

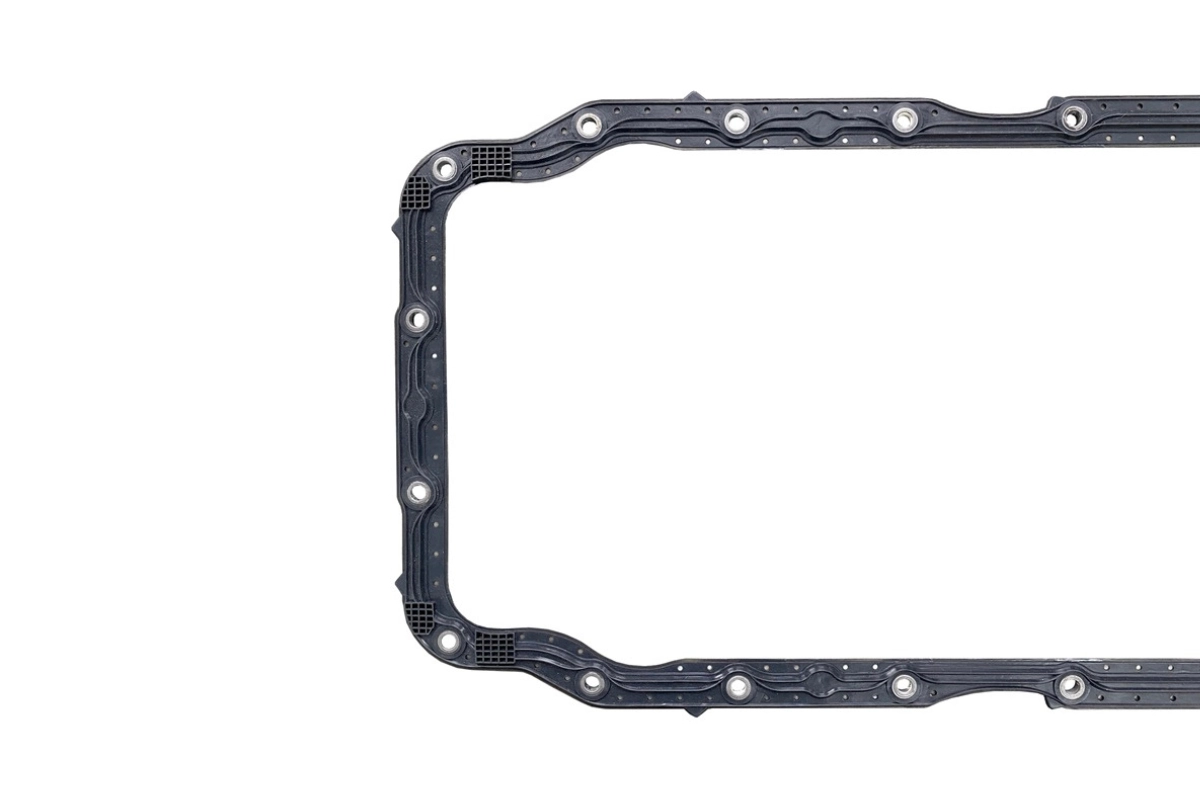

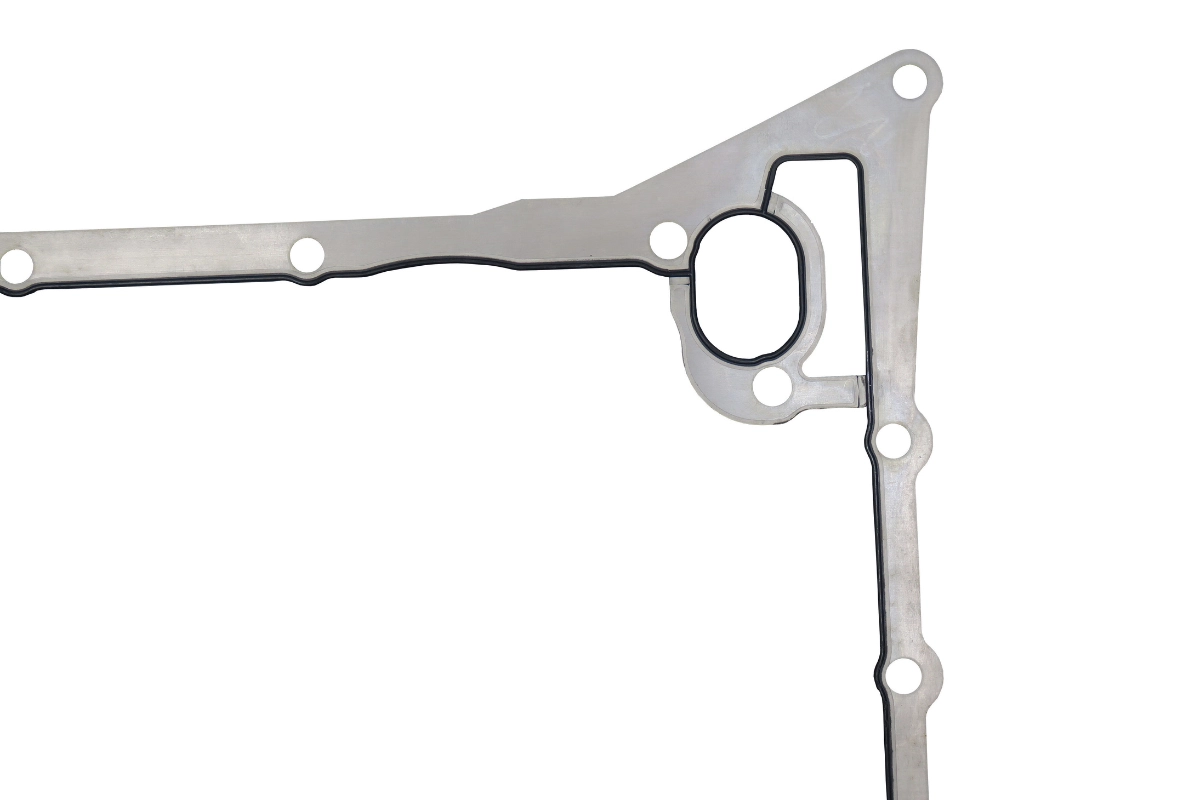

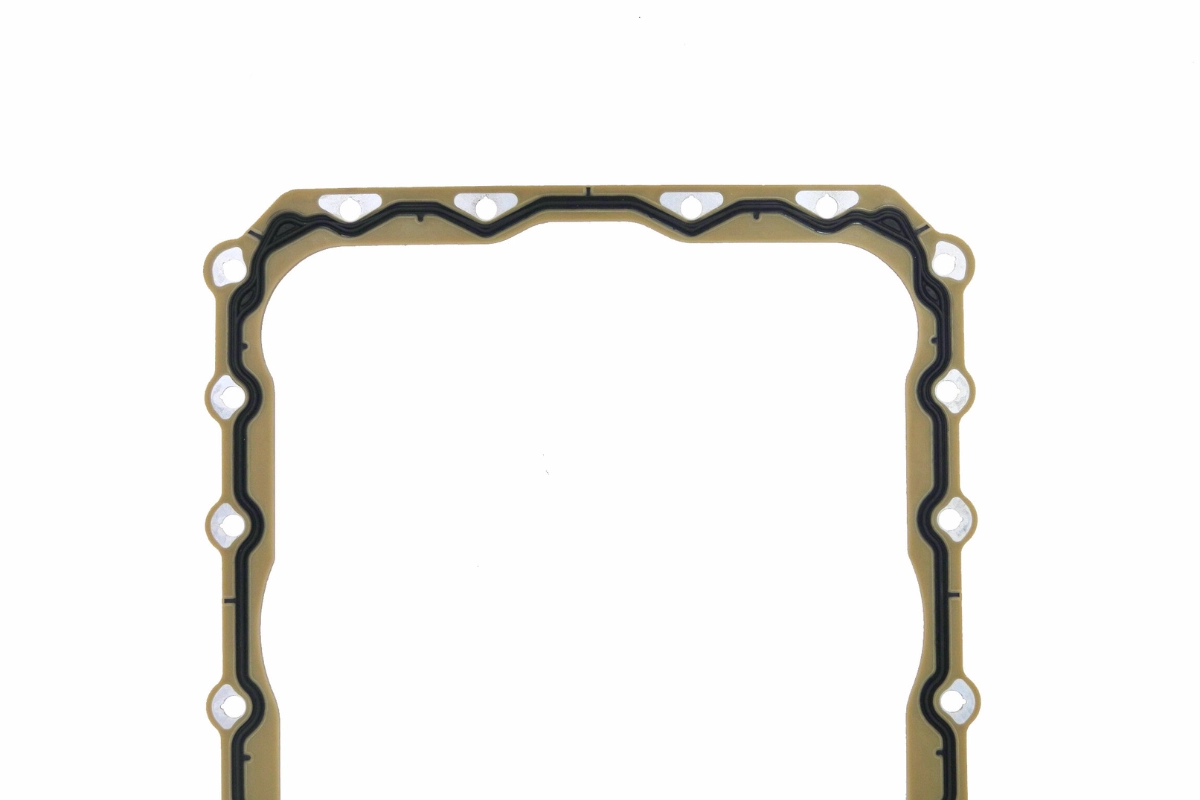

Oil pan gaskets come in several material types, each offering different levels of durability, flexibility, and heat resistance. The right material ensures a proper seal against oil leaks and helps withstand the constant temperature changes and vibrations of the engine. Common oil pan gasket materials include Rubber with Encapsulated Steel Core, Rubber, Steel Bonded with Rubber, and Plastic Bonded with Rubber. Below are brief introductions to each type and their characteristics.

1. Rubber with Encapsulated Steel Core

Example: 4975069 of Cummins

2. Rubber

Example: 3003425C2 of Navistar

3. Steel Bonded with Rubber

Example: 2888747 of Cummins

4. Plastic Bonded with Rubber

Example: 1662905 of Caterpillar

Quick FAQ about Oil Pan Gasket

What causes oil pan gasket to leak?

An oil pan gasket can leak due to heat, vibration, or age-related wear. Over time, the gasket material hardens, cracks, or loses shape, allowing oil to escape between the oil pan and engine block.

Can you reuse oil pan gasket?

Reusing an oil pan gasket is not recommended. Once compressed, the gasket loses its original shape and sealing strength, especially rubber types affected by compression set, leading to potential oil leaks.

What is the best material for oil pan gaskets?

The best oil pan gasket material depends on the engine design and operating conditions. Both rubber (such as ACM or NBR) and rubber with encapsulated steel core are widely used in heavy-duty engines. Rubber types offer flexibility and easy installation, while steel-core versions provide extra strength and stability under higher clamping loads.

MJ Oil Pan Gasket Mating Surface Video

Caterpillar C10/C12 Oil Pan Gasket 1095308

https://www.youtube.com/watch?v=BMlVlQzXPxc

Detroit Diesel Series 60 Oil Pan Gasket 23522279

https://www.youtube.com/watch?v=8d_plyrvepA