Table of Contents

Intake Manifold Gasket Material

An intake manifold gasket, or intake gasket, sits between the engine block and the intake manifold. Its main role is to prevent engine gases from leaking and to keep the gases properly separated from the coolant.

When an intake manifold gasket fails, it can lead to reduced fuel efficiency, engine overheating, and other serious issues. To ensure a reliable seal and long-lasting engine performance, we manufacture our gaskets only with high-quality intake manifold gasket materials that withstand demanding operating conditions.

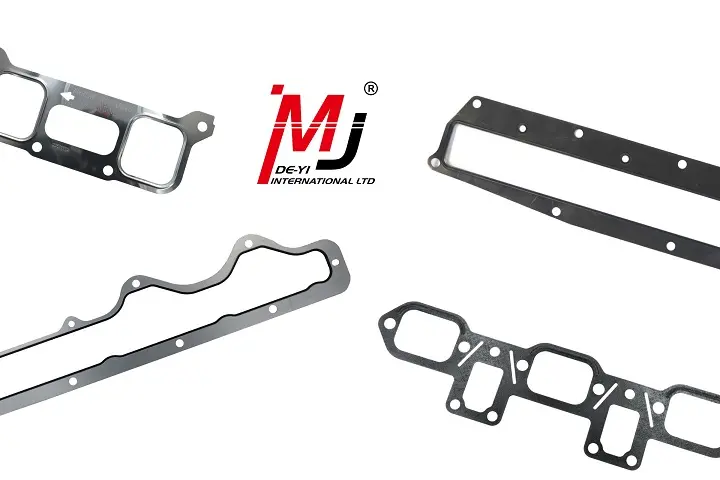

Intake Manifold Gasket Material – Types

Since high-pressure and high-temperature exhaust gases do not pass through the intake side, intake gaskets are not exposed to the same extreme conditions as cylinder head gaskets or exhaust gaskets. Instead, their key function is to provide a reliable seal while resisting wear caused by fluids or gases flowing through the manifold. To maintain proper engine performance, the gasket must also withstand thermal cycling and prevent any leakage that could disrupt the air–fuel mixture.

To handle vibration, pressure changes, and exposure to air and fuel vapors, intake manifold gasket materials are selected for their sealing stability and long-term durability. Common types include:

1. Single Layer Steel

Example Part No.: 23531110

2. Non-Asbestos with Silicone Coating

This material combines a high-density non-asbestos fiber base with a thin silicone elastomer coating. The fiber structure provides compressibility and creep resistance, while the silicone layer improves micro-sealing by filling machining marks or surface scratches. It also offers better resistance against coolant, oil mist, and moderate heat. Such intake manifold gasket materials are commonly chosen for engines requiring both flexibility during assembly and long-term sealing under thermal cycling.

Example Part No.: 590GB312B

3. Steel Bonded with Rubber

Example Part No.: 3688347

4. Rubber Coated Metal (RCM)

Example Part No.: 1842033C1

What is the Best Intake Manifold Gasket Material?

There is no single “best” intake manifold gasket material, as the optimal choice depends on the engine’s operating environment, fluid exposure, and sealing requirements. Common materials and their advantages include:

- Single Layer Steel – Best for applications where the intake and engine block surfaces are precisely machined and require dimensional stability rather than compressibility.

- Non-Asbestos with Silicone Coating – Suitable when flexibility and adaptability to uneven surfaces are needed. The silicone layer enhances resistance against coolant or oil seepage.

- Steel Bonded with Rubber – Ideal for sealing around coolant or oil passages, where minor misalignment or vibration can occur. The rubber edge provides localized conformity without compromising the steel’s strength.

- Rubber Coated Metal (RCM) – Often used in modern engines requiring long-term durability under repeated thermal cycling. The rubber layer resists coolant, fuel vapors, and provides excellent adaptability.

Intake Manifold Gasket Material – Applications

Intake manifold gaskets are important parts of the engine. MJ GASKET provides high-quality intake manifold gaskets for diesel engines. MJ continues to supply durable intake manifold gasket across various applications to meet customer needs.

Heavy-duty Applications

Caterpillar – C7/C9/C10/C12/C11/C13/C15

Cummins – ISX15/8.9L/L9/B6.7L/QSB3.3/QSK19/K38/QSK50/QSK60/QSK95

Detuz – 2.9L

Detroit Diesel – S60/DD13/DD15

MTU – Series 4000

John Deere – 6090

Mack – E7

Navistar – DT466/DT466E/DT570

Paccar – MX-13

Volvo – D12/D13

Pickup Truck Applications

General Moters – Duramax 6.6

Dodge Cummins – B6.7/B5.9

Quick FAQ about Intake Manifold Gasket Material

What are intake manifold gaskets made of?

They are commonly made from single-layer steel, non-asbestos with silicone coating, steel bonded with rubber, or rubber coated metal (RCM), depending on engine requirements.

Which intake manifold gasket material is the best?

As mentioned above, there is no single best option. The right intake manifold gasket material depends on the application—steel for stability, fiber with silicone for flexibility, or rubber-coated types for better fluid sealing.

How do I customize an intake manifold gasket with MJ GASKET?

Provide us with a drawing or sample and specify the changes you need, such as material or thickness. Our team will evaluate your request and offer a gasket solution that meets your requirements.