Exhaust Gasket Material

Table of Contents

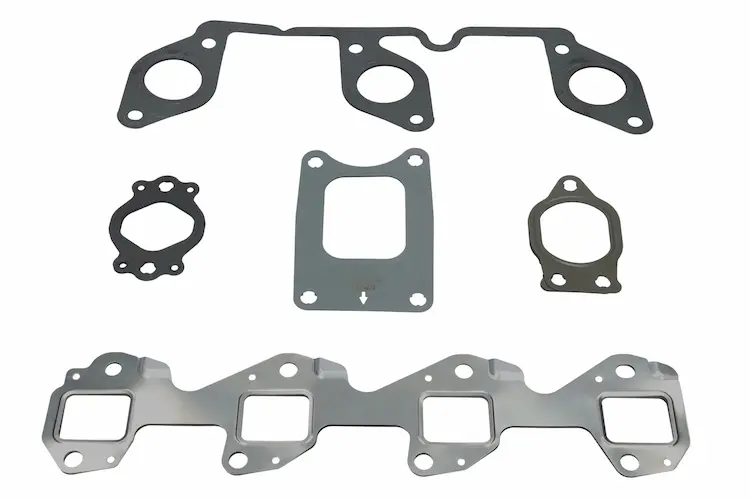

Because exhaust systems face both heat and vibration, gasket materials must be carefully selected. Different materials offer unique advantages in sealing performance, durability, and cost. Below are five commonly used exhaust gasket materials and their applications.

High Temperature Exhaust Gasket Material

Exhaust gasket materials vary by strength and heat resistance. The following are five typical types.

-

Composite Graphite

Composite graphite is known for excellent thermal resistance and flexibility, making it suitable for sealing under fluctuating pressure and temperature.

Example Part No.: 2338014 -

Multi-Layer Steel

Multi-layer steel (MLS), typically made of 2–7 layers joined by rivets or spot welding, offers excellent durability and strength. The layered construction enhances sealing performance under extreme conditions.

Example Part No.: 98002804 -

Multi-Layer Steel with MOS₂ Coating

This variation of MLS includes an MOS₂ coating, which improves surface sealing and reduces the risk of micro-leakage.

Example Part No.: 4386631 -

Ceramic Coating

Ceramic-coated gaskets provide exceptional heat insulation and resistance to thermal shock, making them ideal for high-performance exhaust systems.

Example Part No.: X59514100001 -

Sandwich Type

Sandwich-type gaskets feature stainless steel outer layers with filler material, which can be non-asbestos or graphite. This structure balances strength and adaptability.

Read more about sandwich-type fillers from our case studies: Sandwich-Type Turbo Gasket for Waukesha

Example Part No.: 1115822

Graphite vs. MLS, which seals better?

There’s a saying: Graphite can do better sealing than MLS.

When comparing graphite and MLS as exhaust gasket materials, graphite demonstrates superior sealing performance. Its flexibility allows it to conform to surface irregularities, creating a tighter seal under fluctuating temperatures and pressure. MLS offers strength and durability, but it is less adaptable to uneven surfaces.

Exhaust Gasket Material – Applications

Exhaust gaskets are important parts of the engine. MJ GASKET provides high-quality exhaust gaskets for diesel engines.

MJ keeps providing the best exhaust gasket and various applications for you.

Heavy-duty Applications

Caterpillar – C7/C9/C10/C12/C13/C15/C27/C32/G3500

Cummins – ISX12/ISX15/8.9L/L9/B6.7L/QSB3.3/QSK19/K38/QSK50/QSK60/QSK78

Detroit Diesel – S60/DD13/DD15

MTU – Series 396/Series 2000/Series 4000

John Deere – 6090

Mack – E7

Navistar – DT466/DT466E/Maxxforce 7

Paccar – MX-13

Volvo – D12/D13

Pickup Truck Applications

Ford – 6.0 Powerstroke/7.3 Powerstroke/6.7 Powerstroke

General Moters – Duramax 6.6

Dodge Cummins – B6.7/B5.9

Quick Q&A about Exhaust Gasket Material

What is exhaust gasket material made of?

Common materials include composite graphite, multi-layer steel (MLS), MOS₂-coated steel, ceramic coating, and sandwich-type structures with fillers.

What is the best material for exhaust gasket?

It depends on the application. Graphite provides better sealing, while MLS offers strength and durability.

What is the most commonly used marine exhaust gasket material?

As mentioned above, for large marine engines such as the MTU 4000 series, the marine exhaust gasket material used is steel with ceramic coating, while earlier versions applied steel with MOS₂ coating. For smaller marine engines like MerCruiser V6/V8 dry joint exhaust manifold elbow gaskets, the material is steel combined with rubber and graphite to improve sealing performance.

How do I customize an exhaust gasket?

Please provide a drawing or sample and specify the changes you need, such as material or thickness. Our team will evaluate your request and offer a gasket solution that meets your requirements.