MTU engines are widely used in marine, industrial, and power generation applications. Built for demanding conditions, they power everything from large commercial vessels to luxury yachts. Even in these high-capacity applications, MTU continues to advance the use of sustainable fuels, making internal combustion engines cleaner and more efficient. In the marine sector, MTU is recognized as a leading force, trusted by shipbuilders and operators worldwide for its reliability, engineering expertise, and ability to meet the stringent demands of modern shipping.

Among the popular MTU series are the 183, 396, S60, 2000, 4000 and 8000, each designed for different capacities and applications—from compact high-speed units to large-scale power systems. The table below provides an overview of these series and their typical uses.

MTU Engine Series Overview

| Series | Number of Cylinders Available | Common Applications |

| MTU 183 | 6, 8, 12 | Coastal and offshore marine vessels, passenger and cargo ships, rail traction systems, onshore power generation units, and both fixed-installation and mobile industrial machinery. |

| MTU 396 | 8, 12, 16 | Marine propulsion and auxiliary systems, distributed and backup energy supply, railway traction applications, and heavy-duty vehicle propulsion systems. |

| MTU S60 | 6 | Harbor and coastal workboats, harbor and river towing vessels including pushboats, offshore supply and support craft, commercial fishing trawlers and draggers, and passenger or vehicle ferries. |

| MTU 2000 | 8, 10, 12, 16, 18 | Luxury high-speed yachts, Rapid-response patrol vessels, Law enforcement craft, Marine fire-fighting vessels. |

| MTU 4000 | 8, 12, 16, 20 | Offshore and harbor workboats, passenger and vehicle ferries, government-operated vessels, harbor and ocean-going tugs, cargo barges, and large luxury sailing yachts. |

| MTU 8000 | 16, 20 | High-speed commercial vessels with heavy payload capacity, naval ships, and other military-grade marine craft. |

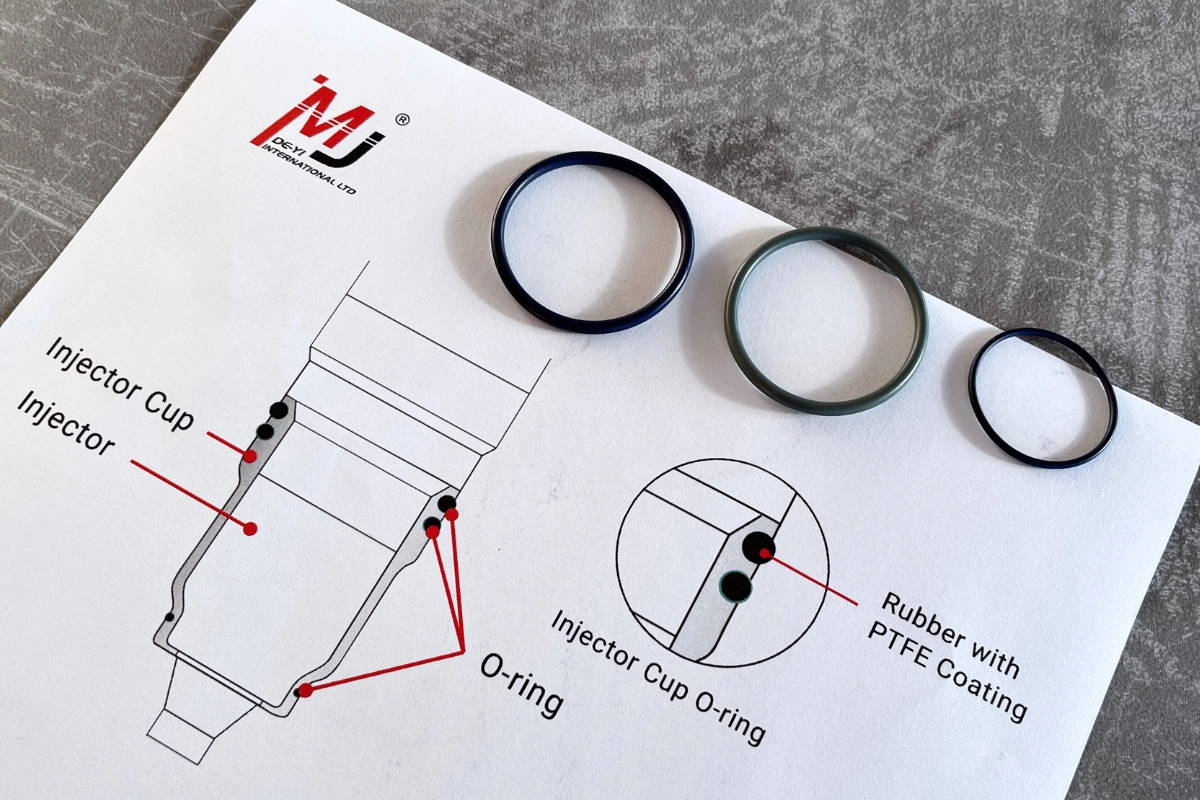

In demanding applications such as marine, power generation, and heavy industrial operations, MTU engines must operate reliably under continuous load. Poor-grade or ill-fitting components can cause early wear, unexpected repairs, and expensive downtime. Well-engineered gaskets and seals are key to maintaining reliable operation and preventing avoidable losses.

MTU Gaskets and Seals – What We Supply

Our range covers critical sealing points across the engine:

| * Cylinder head gasket * Sealing plate * Hand Hole Cover Gasket * Injector Seal |

* Intake manifold gasket * Exhaust manifold gasket * Turbocharger gasket * Valve cover gasket * Heat exchanger gasket |

|

Among the various MTU engine series, the 183, 396, 2000, and 4000 are among the most common in the markets we serve. Below is an outline of the key gaskets and seals we supply for these engines.

MTU 183 Engine Gaskets

For the MTU 183 series, our supply focuses on replacement plate heat exchanger (PHE) gaskets, essential for maintaining effective cooling performance in marine and industrial applications. Available part numbers include 8692030081, 8692030082, 8692030083, 8692030084, 8692030085, and 8692030123. These gaskets are manufactured to match OEM specifications, ensuring proper fit and reliable sealing in demanding operating conditions.

Read more: Engine Rebuild Plate Heat Exchanger Gasket

MTU 396 Engine Gaskets

For the MTU 396 series, we supply cylinder head gaskets, cylinder head cover gaskets, and plate heat exchanger (PHE) gaskets. These components are made to maintain secure sealing under the high pressures and temperatures typical of marine and industrial operations. Available part numbers include 5550161420, 5500160121, 8499970052, and 8499970053, all produced to meet OEM specifications for fit and durability.

MTU 2000 Engine Gaskets

The MTU 2000 engine gasket range includes head gaskets, outer sealing plates, inner sealing plates, cylinder head cover gaskets, plate heat exchanger gaskets, and other related sealing parts. These gaskets are engineered to provide reliable sealing for high-speed marine vessels, patrol craft, and other demanding applications where the MTU 2000 series is commonly used.

Learn more: MTU 2000 Engines Gaskets & Seals

MTU 4000 Engine Gaskets

For MTU 4000 engines powering large vessels and heavy-duty power systems, we supply a complete range of gaskets and seals — including head gaskets, cylinder head seal rings, hand hole cover gaskets, valve cover gaskets, exhaust gaskets, intake gaskets, PHE gaskets, and more upon request. These components are made to handle the high combustion pressures, thermal cycling, and vibration that MTU 4000 engines face in continuous operation.

Learn more: MTU 4000 Engines Gaskets & Seals

MTU engines are widely deployed in commercial marine fleets and workboat operations, where equipment availability is directly tied to contractual obligations and operating margins. In such environments, even minor gasket failures can cause leaks that result in costly repairs, unplanned downtime, and operational delays.

Selecting a gasket manufacturer that complies with industry standards and maintains strict quality control is vital to avoid these issues. At MJ Gasket, every part is made to match the intended application, verified with precision measuring equipment, and produced without cutting corners with integrity as our highest manufacturing standard.

If you are reviewing your MTU engine gasket requirements, share your part numbers with us to check availability and discuss your sourcing needs.

Quick FAQ

What is the MOQ for MTU engine gaskets?

MOQ varies by part number. Share your required quantity so we can confirm availability and production schedule.

How can I request a quotation?

Send us the OEM part numbers, required quantities, and destination so we can prepare an accurate quote.

Can I get samples for quality inspection?

Yes. Samples of selected MTU engine gaskets can be provided, with shipping costs typically covered by the customer. Please contact MJ Gasket to confirm sample availability for your required part numbers.

How can we meet in person and talk directly?

We exhibit at two major U.S. workboat shows every year — the Fort Lauderdale International Boat Show and the International WorkBoat Show in New Orleans. You’re welcome to visit our booth and discuss your requirements face-to-face. It’s also a great opportunity to examine our gaskets in person and verify their quality before making purchasing decisions.