A banjo fitting is a fluid transfer fitting commonly used in diesel engines and hydraulic systems. Its name comes from its ring-shaped design, which resembles a banjo musical instrument. A typical banjo fitting assembly includes a banjo union, a hollow banjo bolt, and banjo bolt washers used for sealing. By allowing fluid to pass through a compact connection while maintaining flexible line orientation, banjo fittings are widely used in fuel systems, oil lines, and various hydraulic applications where reliable banjo seal performance is required.

Why is it called a “BANJO” Fitting?

A standard banjo fitting assembly typically includes three main components: a banjo union, a hollow banjo bolt that passes through the center, and banjo bolt washers installed on both sides to create a sealed fluid connection. The name has nothing to do with music, it simply reflects the fitting’s distinctive geometry, which makes it easy to recognize across many fluid systems.

What is banjo fitting used for?

A banjo fitting is used to route fluid through a compact connection where space, clearance, and line orientation are critical. Its ring-shaped design allows fluid to flow through the connection while keeping the hose or tube close to the mounting surface. This makes it especially effective in tight assemblies where straight or angled fittings would interfere with surrounding components.

In real systems, banjo fittings help manage fluid paths without forcing rigid alignment, which is why they are widely used in fuel injector lines, hydraulic circuits, turbocharger oil feeds, engine cooling systems, etc.

What is banjo bolt? What is the purpose of a banjo bolt?

Its purpose goes beyond fastening. The banjo bolt controls how fluid enters the connection while holding the entire assembly together. When combined with banjo bolt washers, it creates a sealed path that supports pressure, maintains flow continuity, and keeps the overall connection compact.

Why banjo bolt washers matter for sealing?

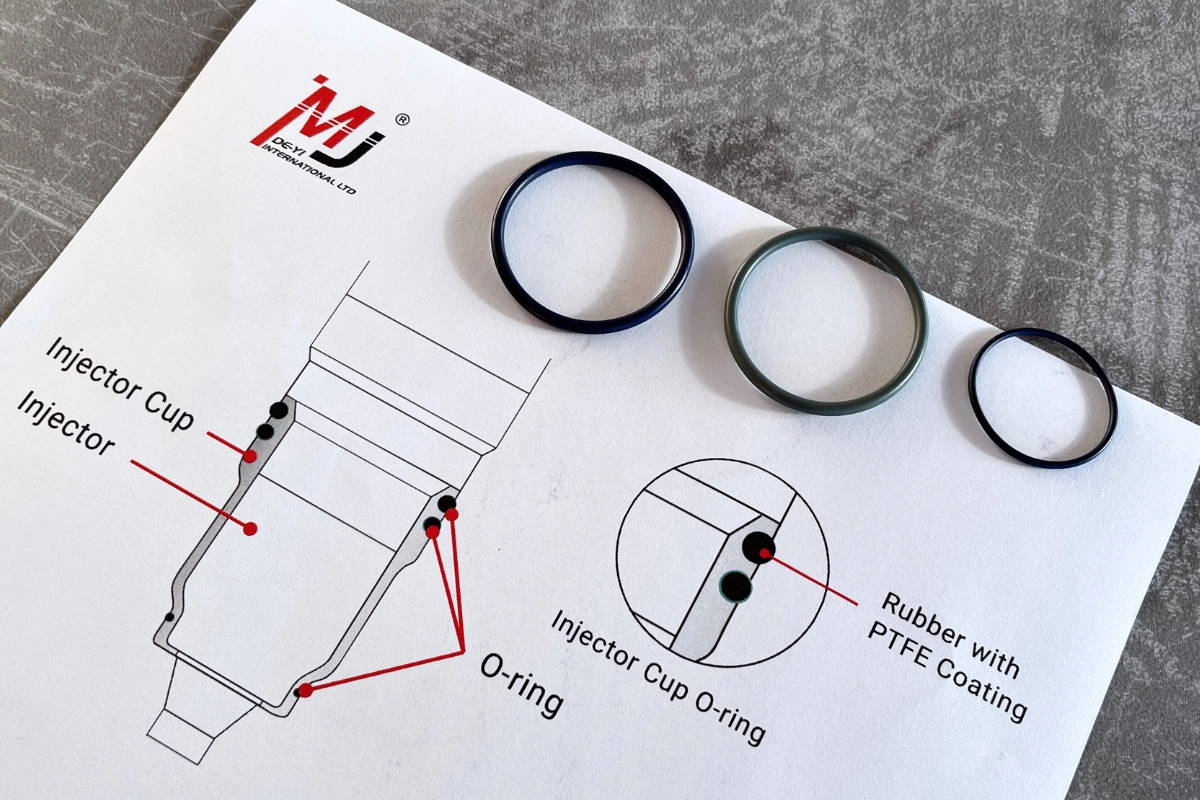

Banjo bolt washers are installed on both sides of the banjo union and are compressed when the banjo bolt is tightened. This compression creates a controlled seal between flat mating surfaces, allowing fluid pressure to be contained without relying on thread deformation. Even minor inconsistencies in washer material or surface contact can result in seepage under pressure or thermal cycling.

In practice, banjo washers are available in several forms. The most common configuration is the connected banjo seal, where two washers are linked together as a single piece. This design helps maintain correct washer positioning during assembly and reduces the risk of installation errors, especially in high-volume or space-constrained environments.

Single-piece banjo washers are also used in some applications and are installed individually on each side of the banjo union, depending on system layout and assembly requirements.

Material selection plays a critical role in sealing behavior. Common banjo washer materials include metal bonded with rubber, copper, and rubber-coated metal. Each material offers different characteristics in terms of compressibility, surface conformity, and resistance to pressure, temperature, and fluid media. As a result, banjo bolt washers are not simply spacers, they are engineered sealing components that directly affect the long-term performance of the entire banjo fitting assembly.

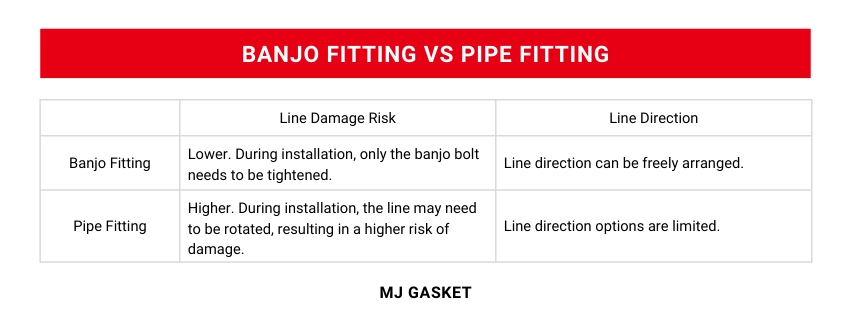

Banjo Fitting vs Pipe Fitting

When comparing banjo fittings and pipe fittings, the differences mainly appear in the load applied during installation and the flexibility of line orientation.

Installation behavior

During installation, a banjo fitting only requires tightening the banjo bolt, and the hose or line itself does not need to rotate. This effectively reduces the risk of line damage caused by twisting. In contrast, pipe fittings often require the line to rotate as the fitting is tightened, which makes twisting and installation stress more likely and increases the risk of damage.

Line direction

Another difference lies in line orientation. Banjo fittings allow the line direction to be adjusted freely and are especially suitable for space-limited or complex layouts. Pipe fittings offer relatively limited directional flexibility, which places more restrictions on routing options.

Application context

Banjo fittings are often seen in compact systems where routing flexibility matters, while pipe fittings are commonly used in more straightforward, fixed-direction layouts.

Applications of banjo bolt washers in diesel engines

Banjo bolt washers are widely used in various diesel engines, and their designs are adjusted according to system configuration and operating conditions. Although the sealing principle is the same, the structure and usage of the washers vary depending on the engine platform and assembly requirements.

6.6 Duramax Banjo Seal

In 6.6L Duramax engines, banjo seals commonly use a connected banjo seal design, where two washers are connected together, to assist with positioning during assembly and to improve consistency in high-volume operations.

In the fuel system, the MJ-LB7FUEL1 fuel return line seal kit is used for Duramax LB7 engines. The kit includes 98065992 ×1 and 97228933 ×4.

Other fuel-related locations include 97250485 (fuel pressure relief area), 12630832 (LML fuel feed pipe), and 98340724 (FICM fuel line banjo seal for LB7 / LLY engines).

In the turbocharger oil supply system, 12627897 is used for the turbo oil inlet on Duramax LML engines, while 97373522 is commonly used on turbo oil lines for LB7 and LLY engines.

Cummins Banjo Seal

Cummins engines commonly use single-piece banjo washers, installed separately on each side of the banjo fitting. The sealing principle is the same, but the washer format reflects differences in component layout, available space, and assembly practices.

On Cummins B6.7 engines, banjo washers such as 3963983 and 3963990 are mainly used in fuel system locations, including fuel filter plumbing, fuel transfer pumps, and fuel filter assemblies.

For turbocharger plumbing and engine coolant-related areas, 4934278 and 4934279 are commonly used.

Quick FAQ about Banjo Bolt and Banjo Bolt Washers

What are banjo fittings?

Banjo fittings are fluid transfer fittings that route fluid through a compact, ring-shaped connection, commonly used in fuel, oil, brake, and hydraulic systems where space and line orientation matter.

What is banjo bolt?

A banjo bolt is a hollow, cross-drilled bolt that secures a banjo fitting while allowing fluid to pass through its internal channels.

Why is it called a banjo bolt?

It is called a banjo bolt because it is used with a banjo union, whose ring-shaped geometry resembles a banjo musical instrument.

How many washers go on a banjo bolt?

Banjo bolt washers come in two common forms: single-piece washers and connected banjo seals. With single-piece banjo washers, two washers are required, one on each side of the banjo fitting. With a connected banjo seal, only one piece is used, as it connects two washers together for proper positioning.

Can you reuse banjo bolt washers?

In most cases, banjo bolt washers should not be reused, especially metal or rubber-bonded washers, as compression during installation can reduce their sealing effectiveness.