A cylinder head gasket is vital for keeping the combustion chamber, coolant passages, and oil channels properly sealed within an engine. Once it fails, the consequences can be both expensive and harmful. Recognizing the early signs of a blown head gasket is crucial to protect the engine from severe damage and unplanned downtime.

When a head gasket goes bad, it may present several noticeable issues that signal failure. However, replacing a head gasket is not a low-cost repair—professional service at a shop can be a significant investment. That is why accurate diagnosis is critical; misjudging the problem can make the repair even more costly.

With over 40 years of experience producing gaskets for heavy-duty engines, we know how much gasket material selection and proper maintenance impact long-term durability. In the following section, we highlight the key head gasket symptoms every operator and technician should watch for.

Table of Contents

Blown Head Gasket Symptoms

Symptom #1: Coolant and Oil Mixing

One of the most common blown head gasket symptoms is the mixing of coolant and engine oil. The purpose of a head gasket is not only to prevent combustion gases from escaping but also to seal the cooling system and oil passages. When the gasket fails in these areas, high-pressure oil may be forced into the coolant, and when the engine is off, pressurized coolant can flow back into the oil. This cross-contamination leads to milky engine oil or coolant with an oily film. Such mixing reduces both lubrication and cooling performance, accelerating engine wear. It is one of the most common and clearest signs of a blown head gasket, requiring immediate inspection and repair.

Symptom #2: Engine Overheating and Coolant Loss

Overheating is one of the most critical head gasket symptoms and should never be ignored. A damaged gasket may allow oil to leak into the coolant system, reducing its ability to regulate engine temperature. This quickly leads to overheating, which can warp cylinder heads or even crack the engine block. In addition, a sudden loss of coolant from the radiator can also point to gasket failure. If you frequently find yourself refilling the radiator or notice weakened coolant strength, it may indicate one of the early signs of a blown head gasket. Checking coolant levels regularly is an effective way to spot this problem before it worsens.

Symptom #3: External Leaks

Another clear indicator of a faulty head gasket is white smoke from the exhaust. This occurs when coolant seeps into the combustion chamber and burns as steam, producing thick white smoke and sometimes causing misfires during startup. Left untreated, this can cause serious engine damage. In some cases, gasket failure may also present as external leaks, visible as damp streaks or “steam-cleaned” spots along the engine block where coolant evaporates. Even though external leaks may seem less severe, they are still important head gasket symptoms that can lead to overheating if ignored. Both conditions are undeniable signs of a blown head gasket that require immediate attention.

Key Sealing Points to Prevent Common Head Gasket Symptoms

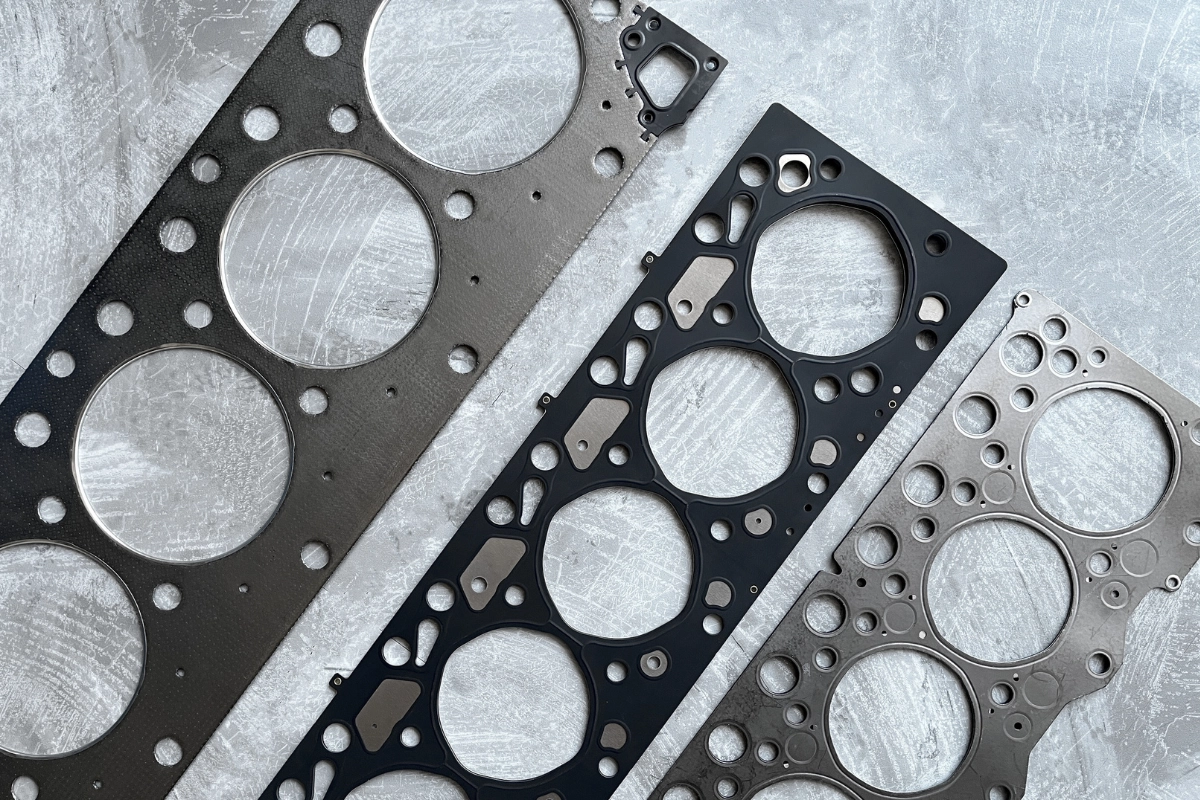

The signs of a blown head gasket highlight the importance of sealing in heavy-duty engines. A cylinder head gasket must withstand high temperatures, combustion pressure, coolant, and oil. When sealing fails, issues like overheating, white smoke, or fluid mixing occur. Next, we will take graphite heavy-duty cylinder head gaskets as an example to explain key sealing points for reliable performance.

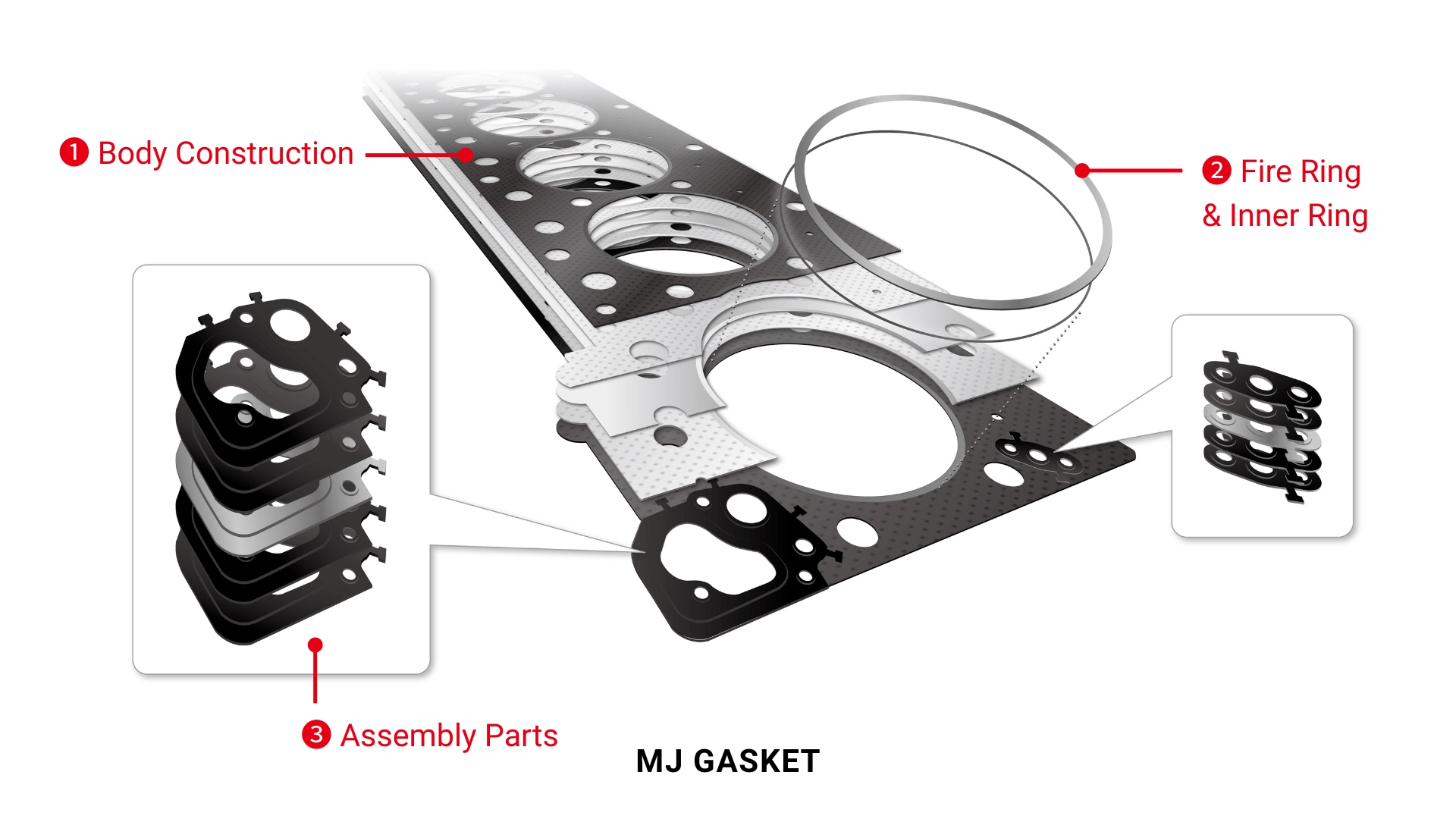

Key Sealing Point #1: Head Gasket Body Construction

Heavy-duty cylinder head gaskets are engineered to endure harsh operating conditions. A five-layer build combines a stainless-steel perforated core with advanced graphite facings, delivering enhanced stiffness and structural integrity. The flexible graphite layer adapts to surface irregularities, providing reliable fluid sealing, minimal relaxation over time, and strong resistance against extreme heat and chemical exposure. This robust body construction helps lower the likelihood of leaks that can develop into head gasket symptoms commonly seen in heavy-duty diesel applications.

Key Sealing Point #2: Fire Ring & Inner Ring

The fire ring and inner ring are critical to sealing the combustion chamber. A movable fire ring design allows greater flexibility and creates an additional seal around the cylinder bore. This prevents combustion gases from escaping, one of the most serious signs of a blown head gasket. In high-horsepower diesel engines, a properly machined fire ring provides greater reliability under extreme stress. Without this protection, the gasket can fret against the cylinder head, eventually cracking and failing, which directly leads to severe blown head gasket symptoms.

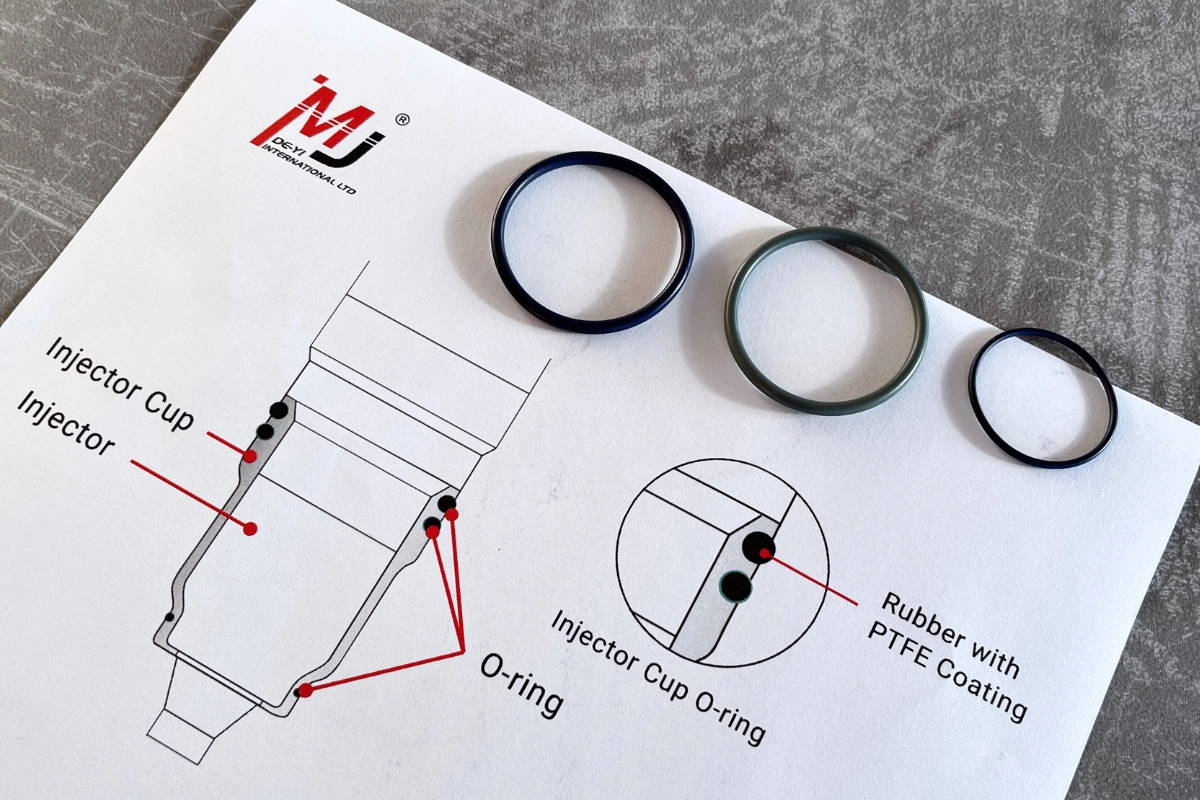

Key Sealing Point #3: Assembly Parts

Sealing around coolant and lubrication holes is equally important. Heavy-duty cylinder head gaskets often incorporate reinforced materials such as rubber coatings or metal inserts, distinct from the main body construction. These reinforcements strengthen sealing under high pressure and temperature, effectively preventing fluid leaks. By reducing oil and coolant cross-contamination, this design minimizes the risk of overheating, white smoke, or fluid mixing—all common head gasket symptoms that signal early stages of failure. Reliable assembly part sealing is essential to avoiding the costly repairs associated with signs of a blown head gasket.

Quick Q&A about A Blown Head Gasket

1. What are the symptoms of a blown head gasket?

The most common blown head gasket symptoms include coolant and oil mixing, engine overheating, coolant loss, white smoke from the exhaust, and external leaks. Each of these head gasket symptoms signals a serious sealing failure that should be addressed immediately.

2. What causes a blown head gasket?

A blown head gasket is often caused by engine overheating, poor sealing materials, improper installation, or excessive cylinder pressure. These conditions can lead to head gasket blown.

3. Is it worth fixing a blown head gasket?

Yes. Ignoring the signs of a blown head gasket can cause engine overheating, warped heads, cracked blocks, or even total engine failure. Overheating may also create driving safety risks, making timely repair the smarter and safer choice.

4. How to prevent blown head gasket?

Regularly maintain the cooling system, monitor fluid levels, and use high-quality head gaskets with strong sealing materials.

5. Should I use an aftermarket head gasket?

Yes, quality aftermarket gaskets are a reliable choice if they meet OEM standards. Many heavy-duty aftermarket options use advanced materials that help prevent common head gasket symptoms and reduce the risk of failure. Read more:

OEM vs Aftermarket Diesel Engine Gasket