VGT Turbo, Twin Turbo, and Two Stage Turbo

MJ GASKET specializes in providing precision sealing solutions for heavy-duty diesel engines, with turbo gaskets being one of our core product strengths. Turbochargers are essential components that directly impact engine power and efficiency, particularly under the high-load conditions of commercial diesel applications.

In this article, we take a closer look at three common turbo configurations used in heavy-duty engines: VGT Turbo (Variable Geometry Turbo), Twin Turbo, and Two Stage Turbo.

We’ll explain how each system functions, what it means for engine performance, and why having the right sealing solution is critical to long-term reliability.

VGT Turbo (Variable Geometry Turbo)

What Is a VGT Turbo?

A Variable Geometry Turbo (VGT) uses adjustable vanes inside the turbine housing to control the flow of exhaust gases. These vanes change position based on engine speed and load, allowing the turbo to deliver optimal boost across a wide RPM range. It is usually equipped with a turbo actuator, which electronically or pneumatically adjusts the vane angles in real time, ensuring precise response and improved engine control.

Application Examples: Cummins B6.7, ISX15

Key Benefits of VGT Turbo Systems

- Provides strong low-end torque and responsive acceleration

- Adjusts boost pressure dynamically across the RPM range

- Improves fuel efficiency under varying engine loads

- Reduces turbo lag without sacrificing top-end performance

Notes from MJ’s Material Consultant

Turbocharger systems, especially in high-output diesel engines like the Cummins B6.7 and ISX15, operate under extreme heat, pressure, and vibration. In this environment, even the smallest leak at the turbo flange, actuator housing, or oil channel can lead to power loss, pressure imbalance, or accelerated wear.

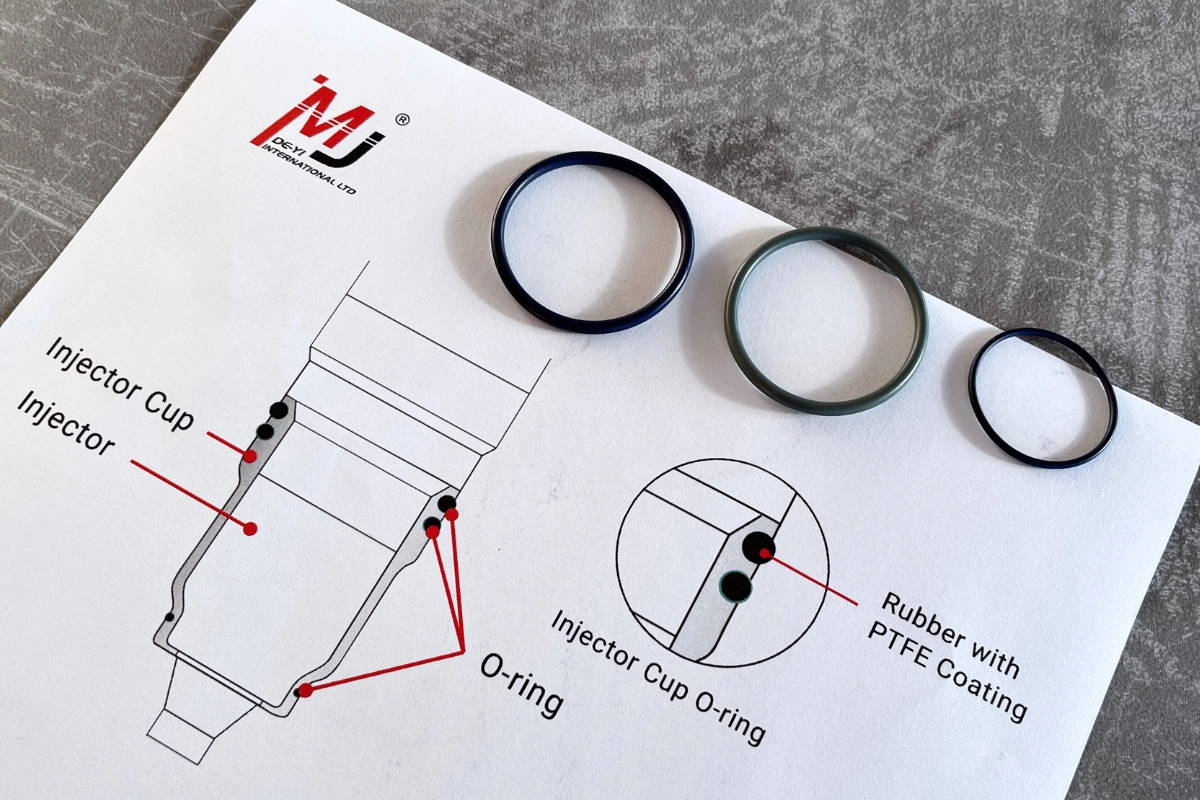

For VGT applications, the actuator seal becomes a critical point of failure if not properly sealed, as it directly affects vane movement and boost control. Precision in gasket and seal material thickness, surface coating, and fitment is essential, especially during prolonged high-load operation.

More about Holset VGT Turbo Actuator Seals

Twin Turbo

What Is a Twin Turbo Setup?

A twin turbo system uses two turbochargers working together to increase intake air volume and improve engine performance. In a parallel configuration, both turbos are identical in size and operate simultaneously. Each turbo processes exhaust gases from a separate group of cylinders, typically one bank in a V-type engine or split evenly in an inline engine. This setup increases total airflow and enables better boost response by reducing the load on each turbo.

Application Example: Ford EcoBoost 3.5L

Key Benefits of Twin Turbo Configurations

- Increases total airflow for enhanced power output

- Improves boost response by splitting the exhaust load

- Provides balanced pressure distribution across engine banks

- Simplifies tuning and maintenance compared to sequential systems

MJ Gasket Material Consultant’s Note

Twin turbo systems, particularly those using a parallel configuration, rely on precise pressure balance between the two turbos to deliver smooth and consistent boost. Any sealing failure at the turbo flanges, cross-bank exhaust joints, or oil return lines can cause imbalance, efficiency loss, or premature wear on one side of the system.

Because each turbo operates under slightly different thermal and vibrational conditions depending on its position, gaskets must be manufactured in matched sets with consistent thickness and material integrity.

Two Stage Turbo

What Is a Two Stage Turbo System?

A two stage turbo system uses two turbochargers of different sizes arranged in sequence to manage boost across the full RPM range. The smaller, high-pressure turbo responds quickly at low engine speeds to deliver immediate boost. As RPM increases, the larger, low-pressure turbo takes over to maintain airflow and pressure. This staged configuration minimizes turbo lag and ensures smooth, continuous power delivery across the entire speed range.

Application Examples: MAN D2862 LE 456/436/476/489/483

Key Benefits of Two Stage Turbocharging

- Delivers smooth and continuous boost from low to high RPM

- Provides higher compression efficiency where single-stage setups fall short

- Enhances low-speed torque and ramp-up response

- Allows greater control over boost management across operating conditions

MJ Gasket Material Consultant’s Note

Two stage turbocharging systems operate under complex pressure and temperature gradients due to the sequential flow between a small high-pressure turbo and a larger low-pressure unit. Sealing performance becomes even more critical in this configuration, as pressure mismatches between stages can directly affect boost delivery and engine responsiveness.

No matter how advanced the turbo system, sealing performance is non-negotiable. Turbo gaskets are essential to maintaining boost integrity, controlling heat flow, and protecting engine performance over time. From flange sealing to actuator interface points, every connection must be precise and reliable.

Consistency in material quality, thickness control, and sealing reliability is essential for supporting high-performance diesel systems. Even a minor leak can lead to power loss, pressure imbalance, or long-term component wear.

Explore Turbo Gaskets for Heavy-duty Engines

For more information about turbo gasket materials or sealing solutions, please contact our technical team.