MJ Gasket has invested in two advanced precision measurement machines, the IM-7000 and VR-6200, to enhance the accuracy and quality of their diesel engine gaskets. The manufacturing process of these gaskets, which are essential mechanical seals used to fill gaps between mating surfaces, heavily relies on such sophisticated tools. Precision measurement is critical in ensuring tight seals and preventing oil leaks in diesel engines. This article delves into how MJ Gasket leverages these precision measurement tools in their gasket manufacturing process, illustrating their commitment to producing high-quality products for diesel engines.

MJ Gasket Makes Good Use of Technology

To keep supplying high-quality engine products for you, MJ decides to cooperate with our new partner that is called” Image Dimension Measurement System” (IM-7000 Series) which provides precision inspection and documentation services to enhance our quality control.

Image Dimension Measurement System (IM-7000 Series)

Higher Accuracy Data

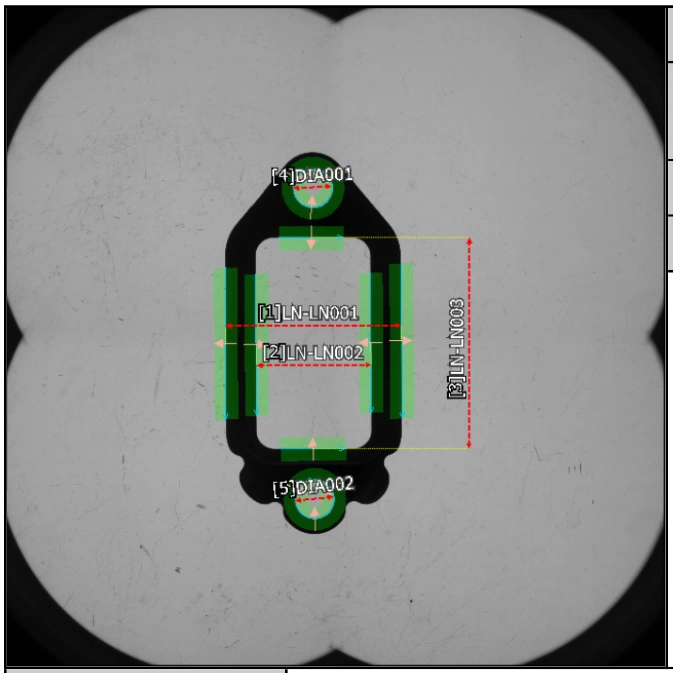

The Image Dimension Measurement System provides precision inspection service. It has multiple functions for different purposes. It operates automatically and offers higher accuracy to prevent the traditional manual measurement error.

Applicable to Various Types of gaskets

Through this equipment, we can re-examine dimension details, for distinct shapes of gaskets, such as thickness, multiple diameters, and angles to make sure if they are approved or needed to be revised.

Detailed Measurement Report

Other than sending actual samples to our customers for quality check, there is another option. With the assist of this new equipment, we can also provide complete measurement documentations beforehand to shorten the operation time for sample approval and increase the efficiency of overall order management.

The photo below illustrates the practical usage of the IM-7000 for measuring gaskets, along with the resulting measurements. Additionally, we have the capability to export this data as a file.

3D Optical Profilometer (VR-6200)

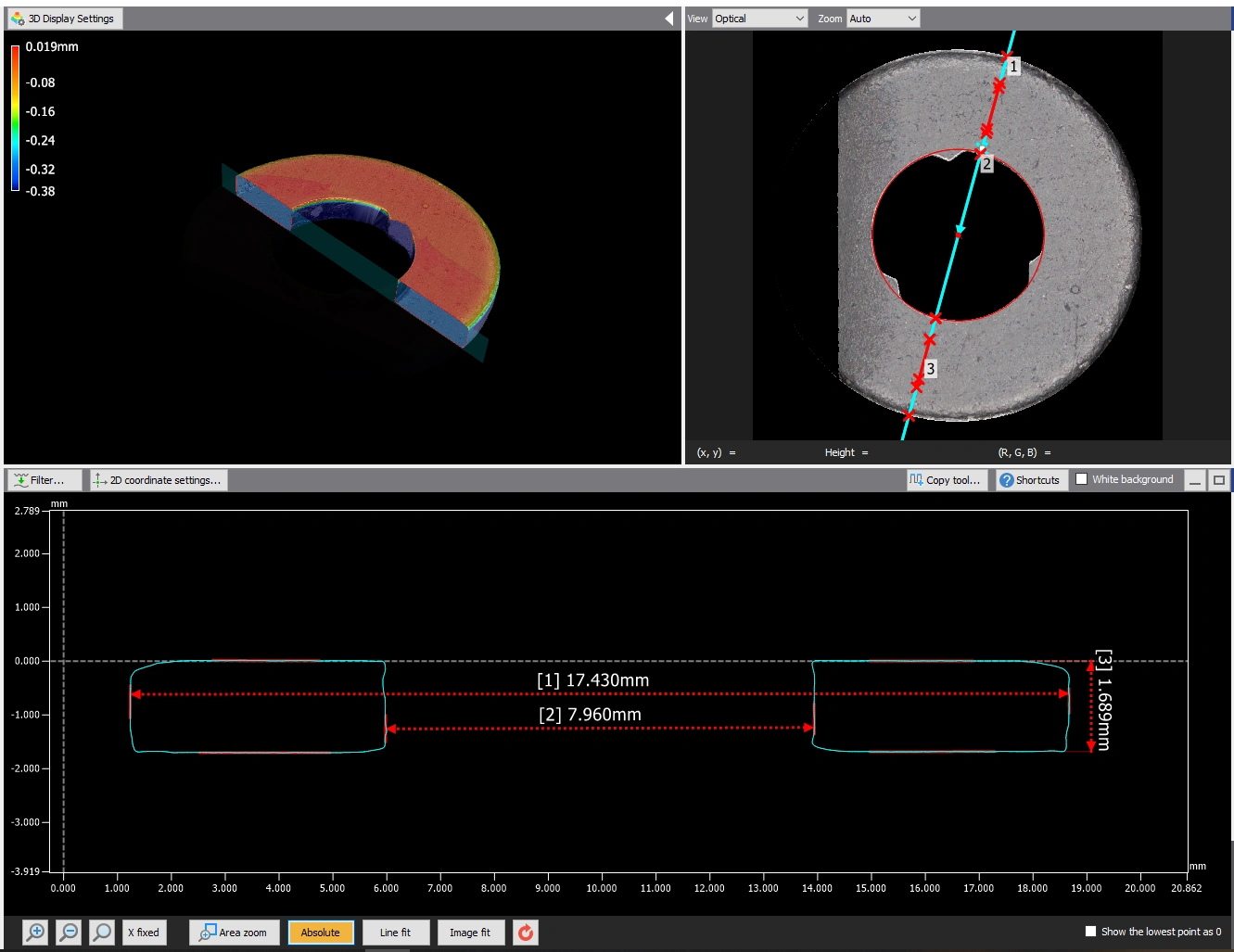

In addition, we have added a brand new multi-functional 3D Optical Profilometer VR-6200 to our arsenal by the end of 2022. This enhancement has taken MJ Gasket’s precision measurement capabilities to the next level.

VR-6200 is a non-contact 3D measurement system.

- High-precision 3D measurement, capable of measuring profiles, flatness, and roughness in just one second.

- Using structured light mode, the VR-6200 is able to fully cover the target surface, providing more detailed sample information. In addition, it integrates multiple measurement systems, allowing for quick and easy measurements of height differences, distances, angles, and various 2D and 3D dimensions. Furthermore, it can also quantify surface roughness and perform GD&T measurements, such as flatness, parallelism, and concentricity.

- Highly automated design enables precise measurements to be possible, regardless of the user’s experience. It automatically determines the sample size, position, and scanning settings. In addition, by using the template function, measurements can be applied to a group of parts, effectively saving time and improving measurement repeatability.

- It is also equipped with an automatic rotating unit, which can replicate the cross-sectional shape without cutting or damaging the sample, significantly expanding the measurement capability. At the same time, the programmed pass/fail inspection function can immediately determine whether the sample meets the design specifications.

The photo below illustrates the practical usage of the IM-7000 for measuring gaskets, along with the resulting measurements. Additionally, we have the capability to export this data as a file.

Interested in reading the full report content? Please contact us and let us know what your needs are.

The Art of Engine Gasket Manufacturing

Manufacturing diesel engine gaskets involves the combination of precision engineering and materials science. These components are typically made from a variety of materials and require different manufacturing techniques to complete. In addition to material selection, precise cutting techniques, molding and compression techniques, quality control measures, and related technologies are also required.

Material Selection

The choice of materials is crucial in the manufacturing process. Graphite, known for its heat resistance and sealing properties, is commonly used for gaskets. On the other hand, rubber gaskets excel in preventing liquid leaks due to their flexibility. Metal gaskets, made from materials such as stainless steel, offer durability and the ability to withstand extreme temperatures.

Custom Gasket Materials – Graphite

Custom MLS (multi-layer steel) Head Gasket, Exhaust Gasket

Custom Gasket Materials – Sandwich Type

Precision Cutting Technology

To securely seal engine components, we need to create precise gaskets. With advanced cutting techniques, we can ensure that the shape and size of the gaskets meet the requirements of different engines. It’s like solving a puzzle, we need to make sure that each gasket is accurately fitted into the engine components to achieve effective sealing.

Die Cutting

Die cutting is a precise process that uses tight tolerances and exacting standards in which you use a machine to cut out shapes. The advantage of die cutting is “dies” are reusable; they can keep the costs down and be more efficient.

CNC Laser Cutting

Laser cutting is a technology that uses laser beams to vaporize materials, resulting in a cut edge. CNC laser cutting uses a computer to control laser directions so that it is more elaborate and precise, and the processes leave edges with a high-quality surface finish. We also have laser marking technology that marks or labels gasket with a laser beam.

Molding and Compression

Once the gasket material is cut into the desired shape, it will undergo a molding and compression process. Compression molding uses heat and pressure to shape the material, enhancing its density and sealing performance. This step is crucial to ensure that the gasket can withstand the pressure and temperature fluctuations within the engine.

Rubber Molding

The process of rubber molding is to use the plasticity of rubber. The first step is to heat the rubber and then use pressure to mold and form the shape to make rubber products. The most common forming methods we use are compression molding and injection molding.

Quality control

The manufacturing process is closely monitored through strict quality control measures. Each gasket undergoes comprehensive inspections for dimensions, surface gloss, and material integrity. Advanced imaging technology and detection systems help maintain the highest standards, ensuring the production of high-quality gaskets for diesel engines.

We understand that the gasket’s tight dimensional tolerances and thicknesses are critical. In pursuit of quality and precision, we continue to invest in new technologies and equipment. Advanced technology provides reliable products!

Your Best Choice for Gasket Manufacturer

Gaskets are inconspicuous but essential, and they are the key to preventing more significant damage; therefore, it is vital to choose a qualified and reliable gasket manufacturer.

MJ Gasket started our business in the early 1980s and always focuses on gaskets for heavy-duty engines and related devices, committing to providing the best gaskets. Also, MJ Gasket has obtained the affirmation of ISO 9001:2015 certification for five consecutive years and is also a GFA certified gasket manufacturer, worthy of your trust! We have already served hundreds of customers for a wide range of industries worldwide. Some industries that use our gaskets are agriculture, heavy-duty, medium-duty, construction, mining, or even marine.

Do you want custom gasket manufacturing? Provide drawings, samples, or numbers; we can deliver it!

What is even better to be a partner with MJ Gasket? We offer below extra services for you to really complete your orders,

- custom marking on your gaskets, printed or laser marking

- custom packaging with or without your own branding

- custom gasket kits as you requested

Contact Us for further assistance from MJ Gasket and request a free sample!