The oil cooler gasket plays a vital role in the engine oil cooler. If your oil leaks before it can perform its job, it may cause your engine to become flammable, seize, and destroy the parts in your engine. This article will let you know how to choose the right gaskets.

Table of Contents

What is Oil Cooler?

An Oil Cooler is designed to keep your engine oil cool at optimal temperature; it’s usually used in Heavy-Duty Industries or Truck Engines. It provides a cooling effect and prevents oil from overheating because that will cause oil to lose its viscosity.

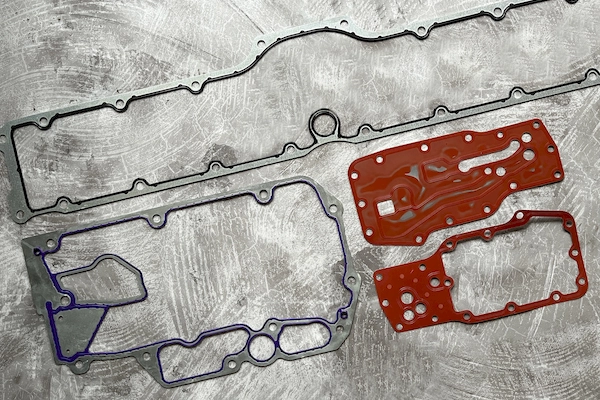

The oil cooler gaskets are typically made from high-quality materials such as rubber or silicone. The gaskets are engineered to withstand extreme temperatures and pressures commonly found in engine environments.

What does an oil cooler gasket do for?

The oil cooler gasket is the most crucial part of keeping the oil cooler working well; it’s designed to keep oil from leaking before it can adequately lubricate the engine components. By maintaining the function of the cooling system, these gaskets help regulate engine temperature, ensuring optimal operating conditions even under heavy loads or high-speed driving.

Furthermore, oil cooler gaskets play a crucial role in preventing contamination of engine oil or coolant, which can lead to corrosion, buildup of debris, and ultimately, engine failure. Their resilience and durability contribute to the overall reliability of the engine, reducing the risk of costly repairs and downtime.

The following six points outline the uses of an oil cooler gasket:

- An oil cooler gasket is a component that seals the connection between the oil cooler and the engine block.

- The oil cooler is a device that lowers the temperature of the oil that circulates through the engine, preventing overheating and damage.

- The oil cooler gasket prevents oil from leaking out of the cooler or into the coolant system, which can cause serious problems for the engine performance and safety.

- The oil cooler gasket also ensures that the oil pressure is maintained at the optimal level, allowing the oil to reach all the parts of the engine that need lubrication.

- The oil cooler gasket is made of durable material that can withstand high temperatures and pressures, but it can wear out over time and develop cracks or holes.

- A faulty oil cooler gasket can lead to oil loss, contamination, overheating, or reduced engine power, so it should be replaced as soon as possible by a qualified mechanic.

Introduction to the manufacturing method of oil cooler gasket

Oil cooler gaskets are essential in engine maintenance, sealing joints between the oil cooler and the engine block or oil filter to prevent oil leakage and maintain optimal oil temperature. These gaskets can be made from rubber, metal, or composite materials, chosen based on application and operating conditions.

Manufacturing methods for oil cooler gaskets include punching, water jetting, and laser cutting. Punching involves molding a bent steel strip into the desired shape, then feeding it through a sheet of gasket material and using a sharp blade to cut the gasket. Water jetting uses a high-pressure water jet to cut through the material, suitable for various shapes and materials without deformation. Laser cutting uses a laser beam for precise cuts, although it may cause flammability issues with some materials.

Selecting the right oil cooler gasket is crucial for engine cooling system performance and longevity. Consider the engine type, cooling requirements, and operating conditions when choosing a gasket. Proper installation and maintenance are also vital to prevent leaks and damage.

Several Types of oil cooler gasket materials

Oil cooler gaskets are vital components of the engine cooling system. They prevent oil from leaking out of the oil cooler and into the engine block, which could lead to overheating and damage. Various types of oil cooler gaskets are available, each differing in materials, design, size, and function. Understanding the main types of oil cooler gasket materials and their roles in the engine cooling system is crucial. Selecting the appropriate oil cooler gasket is essential for maintaining the optimal performance and longevity of the engine cooling system.

Rubber-Metal Bonded Gaskets

Rubber-metal bonded gaskets are custom-molded from various engineering elastomers for high-performance engines and other applications. These gaskets bond to metals such as cold-rolled steel, stainless steel, brass, or aluminum, ensuring compatibility with all elastomer types. The rubber is mechanically secured to the metal during the molding stage, making this process ideal for producing durable components like encapsulated molded steel gaskets, which combine rubber’s flexibility with metal’s stability.

Metal-backed gaskets offer superior durability and resistance to high temperatures compared to rubber oil seals. They include a metal plate that supports the rubber ring, providing extra strength and stability, making them suitable for high-performance engines generating significant heat and pressure. However, these gaskets are more expensive than rubber oil seals.

Learn more:Metal / Plastic Bonded with Rubber | Custom Gaskets Material

RCM | Advanced Coated Steel

To address the sealing issues of oil cooler gaskets, MJ Gasket offers a variety of coatings to meet your needs, including MoS2, ceramic, and rubber.MoS2 coating is a compound known for its ability to withstand high pressure and high temperatures. Many multilayer steel gaskets are coated with MoS2 to effectively resist heat and pressure.

Ceramic coatings can also be applied alongside MoS2 to gaskets for optimal performance. Additionally, we offer rubber coating options. The most common rubber materials used for rubber-coated metal are Nitrile Rubber (NBR) and Fluorocarbon Rubber (FKM). NBR has a heat resistance of approximately 150°C, while FKM can withstand temperatures of up to 250°C. Both of these rubber materials enhance the durability of steel in harsh environments.

Learn more:Steel with Advanced Coating | Custom Gaskets Material

Non-Asbestos Gaskets

Asbestos-free gaskets are significant alternatives to the previously used asbestos-containing gaskets in the fluid sealing industry. While asbestos was valued for its heat resistance, it was banned due to health hazards. Asbestos-free gaskets offer a safe option, eliminating health risks while maintaining excellent heat resistance, making them suitable for high-temperature applications like air compressors, diesel engines, and pipelines.

These gaskets are also ideal for use with water, gasoline, or natural gas, leading to their widespread adoption in various industrial and marine environments. In summary, asbestos-free gaskets are essential replacements that reduce health risks and offer versatility and practical use across many industries.

Can you drive with a leaking oil cooler?

It can be dangerous to drive a vehicle with an oil leak. A small oil leak can grow larger and cause a more expensive repair.

Remember, once oil reaches a specific temperature, it can be flammable, and the engine and other parts may be on fire.

Plus, if the leak worsens while a vehicle is working, it may cause the engine to seize and damage the engine components. Consequently, driving with an oil leak isn’t worth risking.

Why Does the Engine Oil Cooler Gasket Malfunction?

- Incorrect installations: Please make sure you install your oil cooler gasket in the right way.

- Gasket quality: How long an oil cooler gasket can maintain depends on the quality of the gasket.

- Regularly replacing: The gasket didn’t change while engine maintaining or repairing. You should check your engine oil cooler seal while maintaining or repairing it.

- Over time: The oil cooler gasket can fail because of overtime.

What are the symptoms of a bad oil cooler gasket?

Symptoms of a bad oil cooler gasket can manifest in several ways, indicating potential issues with the engine’s cooling system and lubrication process. Here are the key signs to watch out for:

- Oil Leaks: One of the most common symptoms of a failing oil cooler gasket is visible oil leaks around the oil cooler or engine block.

- Overheating Engine: A malfunctioning oil cooler gasket can lead to improper sealing, causing coolant and oil to mix or leak. This can result in inadequate cooling of the engine, leading to overheating.

- Decreased Oil Pressure: A deteriorating oil cooler gasket can result in loss of oil pressure within the engine. As oil leaks or mixes with coolant, the volume of oil circulating through the engine may decrease, leading to a drop in oil pressure.

- Engine Performance Issues: A failing oil cooler gasket can impact engine performance by affecting the lubrication and cooling processes.

How to solve an Oil Cooler Leak?

- Choose a high-quality oil cooler gasket set for your oil cooler; We will discuss it during the next question.

- Find a trusted or high-rated repair workshop and technician.

- Replace your gasket when it is losing its tightness.

How to choose a High-Quality Aftermarket Oil Cooler Seal, Gasket that meets OEM Quality?

You can check if the oil cooler gasket has any flashes and burrs. Besides, check if the materials, dimensions, and duro meet the same OEM.

When some of the OEM gaskets leak, to solve this problem, aftermarket manufacturers change the gasket material to improve. For dimensions and duro, we recommend getting closer to the OEM.

Most importantly, MJ Gasket has trained a professional and reliable team to understand customer needs and solve their problems. Apart from this, we have advanced measuring instruments to ensure our quality is the same as OEM.

Are you looking for an Aftermarket Oil Cooler Gasket Set? At the same time, do you want the products you get to be OEM-level quality? That’s what we offer.

Download our Monthly New Product PDF : Oil Cooler Gasket Kit for Diesel Engines Nov-2022.pdf

Oil Cooler Gasket Set

Oil Cooler Gasket

Oil Cooler Seal

This is not the end of oil cooler gaskets we have. The below brands are also available with MJ.

| -Caterpillar | -Volvo | |

| -John Deere | -Mack | |

| -GM Duramax 6.6L | -Paccar |

If you have any questions, you can check our FAQ page or contact us.